BAB Precision Planetary Gear Units

Reliability

●Spiral gears comfiquration adopted with an engage-ment ratio as twice as the common spur gears, features more smooth running condition, low noise, high output torque and low backclearance.

●Gears are made of alloy metal with premium quality, applied with surface hardness treatment, grinded byhigh-precision grinder, offering great wear-resisting characteristic and impact resistance.

| Model NO | Stage | Ratio | BAB042 | BAB060 | BAB060A | BAB090 | BAB90A | BAB115 | BAB142 | BAB180 | BAB220 | |

| (Mominal Output Torque Tzn) | Nm | 1 | 3 | 20 | 55 | - | 130 | - | 208 | 342 | 588 | 1140 |

| 4 | 19 | 50 | - | 140 | - | 290 | 542 | 1050 | 1700 | |||

| 5 | 22 | 60 | - | 16C | - | 330 | 650 | 1200 | 2000 | |||

| 6 | 20 | 55 | - | 150 | - | 310 | 600 | 1100 | 1900 | |||

| 7 | 19 | 50 | - | 14C | - | 300 | 550 | 1100 | 1800 | |||

| 8 | 17 | 45 | - | 120 | - | 260 | 500 | 1000 | 1600 | |||

| 9 | 14 | 40 | - | 100 | - | 230 | 450 | 900 | 1500 | |||

| 10 | 14 | 40 | - | 100 | - | 230 | 450 | 900 | 1500 | |||

| 2 | 15 | 20 | 55 | 55 | 130 | 130 | 208 | 342 | 588 | 1140 | ||

| 20 | 19 | 50 | 50 | 140 | 140 | 290 | 542 | 1050 | 1700 | |||

| 25 | 22 | 60 | 60 | 160 | 160 | 330 | 650 | 1200 | 2000 | |||

| 30 | 20 | 55 | 55 | 150 | 150 | 310 | 600 | 1100 | 1900 | |||

| 35 | 19 | 50 | 50 | 140 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 17 | 45 | 45 | 120 | 120 | 260 | 500 | 1000 | 1600 | |||

| 45 | 14 | 40 | 40 | 100 | 100 | 230 | 450 | 900 | 1500 | |||

| 50 | 22 | 60 | 60 | 160 | 160 | 330 | 650 | 1200 | 2000 | |||

| 60 | 20 | 55 | 55 | 150 | 150 | 310 | 600 | 1100 | 1900 | |||

| 70 | 19 | 50 | 50 | 140 | 140 | 300 | 550 | 1100 | 1800 | |||

| 80 | 17 | 45 | 45 | 120 | 120 | 260 | 500 | 1000 | 1600 | |||

| 90 | 14 | 40 | 40 | 10C | 10C | 230 | 450 | 900 | 1500 | |||

| 100 | 14 | 40 | 40 | 100 | 100 | 230 | 450 | 900 | 1500 | |||

| (Emergency Stop Torque Tznor | Nm | 1,2 | 3~100 | (3Times of Mominal Output Torque) | ||||||||

| (Nominal Input Speed Nin) | rpm | 1,2 | 3~100 | 5,000 | 5,000 | 5,000 | 4000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| (Nominal Input Speed Nia) | rpm | 1,2 | 3~100 | 10,000 | 10,000 | 10,000 | 8000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| (Micro Backlash PO) | arcmin | 1 | 3~10 | - | - | - | ≤1 | - | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 15~100 | - | - | - | - | ≤3 | ≤3 | ≤3 | ≤3 | |||

| (Redduced Backlash P1) | arcmin | 1 | 3~10 | ≤3 | ≤3 | - | ≤3 | - | ≤3 | ≤3 | ≤3 | S3 |

| 2 | 15~100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | S5 | ≤5 | ||

| (Standard Backlash P2) | arcmin | 1 | 3~10 | ≤5 | ≤5 | ≤5 | - | ≤5 | ≤5 | ≤5 | ≤5 | |

| 2 | 15~100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| (Efficiency) | % | 1 | S97% | |||||||||

| 2 | 15~100 | ≤94% | ||||||||||

| (Weight) | kg | 1 | 3~10 | 0.6 | 1.3 | - | 3.7 | - | 7.8 | 14.5 | 29 | 48 |

| 2 | 15~100 | 0.8 | 1.5 | 1.9 | 4.1 | 5.3 | 9 | 17.5 | 33 | 60 | ||

| (Operating Temp) | ℃ | 1,2 | 3~100 | -10°℃~90℃ | ||||||||

| (Lubrication) | 1.2 | Syntheticlubricationoils | ||||||||||

| (Degree of Gearbox Protection) | 1,2 | IP65 | ||||||||||

| (Mounting Position) | 1,2 | 3~100 | Alldirections | |||||||||

| Noise(n1=3000rpm i=10,No load) | dB(A) | 1,2 | 3~100 | ≤56 | ≤58 | s60 | ≤60 | ≤63 | ≤63 | ≤65 | ≤67 | ≤70 |

Product Detail

Introducing our latest product, the versatile and reliable reducer! Designed to meet various requirements and deliver superior performance, these reducers come equipped with cutting-edge specifications and features.

There are seven different specifications to choose from, including 042, 060, 090, 115, 142, 180 and 220. Customers can flexibly choose the reducer that best suits their needs. Whether you need high torque or a specific reduction ratio, we have you covered.

Speaking of performance, our reducers have a maximum rated output torque of 2000Nm, ensuring excellent power and efficiency. Additionally, they are available in a variety of single-stage reduction ratios (from 3 to 10), giving you greater control and customization options. For those looking for advanced reduction levels, our dual levels include 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90 and 100.

When it comes to reliability, our reducers really excel. Their reduction mechanism adopts a helical gear design, and its tooth meshing rate is more than twice that of ordinary spur gears. This results in smooth operation, low noise levels and high output torque. Additionally, our reducers are designed with low clearance features ensuring seamless and precise performance.

To ensure durability and service life, the gears in our reducers are made of high-quality alloy materials. These gears are case-hardened and carefully machined using high-precision gear grinders, resulting in wear-resistant, impact-resistant and tough parts. This ensures our reducers can withstand the most demanding applications and environments.

In short, our reducers offer unparalleled performance, reliability and durability. Their wide range of specifications, high torque capabilities and advanced reduction ratios make them suitable for a variety of industries and applications. Backed by our commitment to quality and customer satisfaction, we are confident that our reducers will exceed your expectations and provide optimal performance for your specific needs. Experience the power and precision of our reducers today!

Application

1. Aerospace field

2. Medical industry

3. Industrial robots, Industrial Automation, CNC machine tool manufacturing industry automotive industry, printing,agriculture, food industry, enviroment protection engineering, warehouse logistics industry.

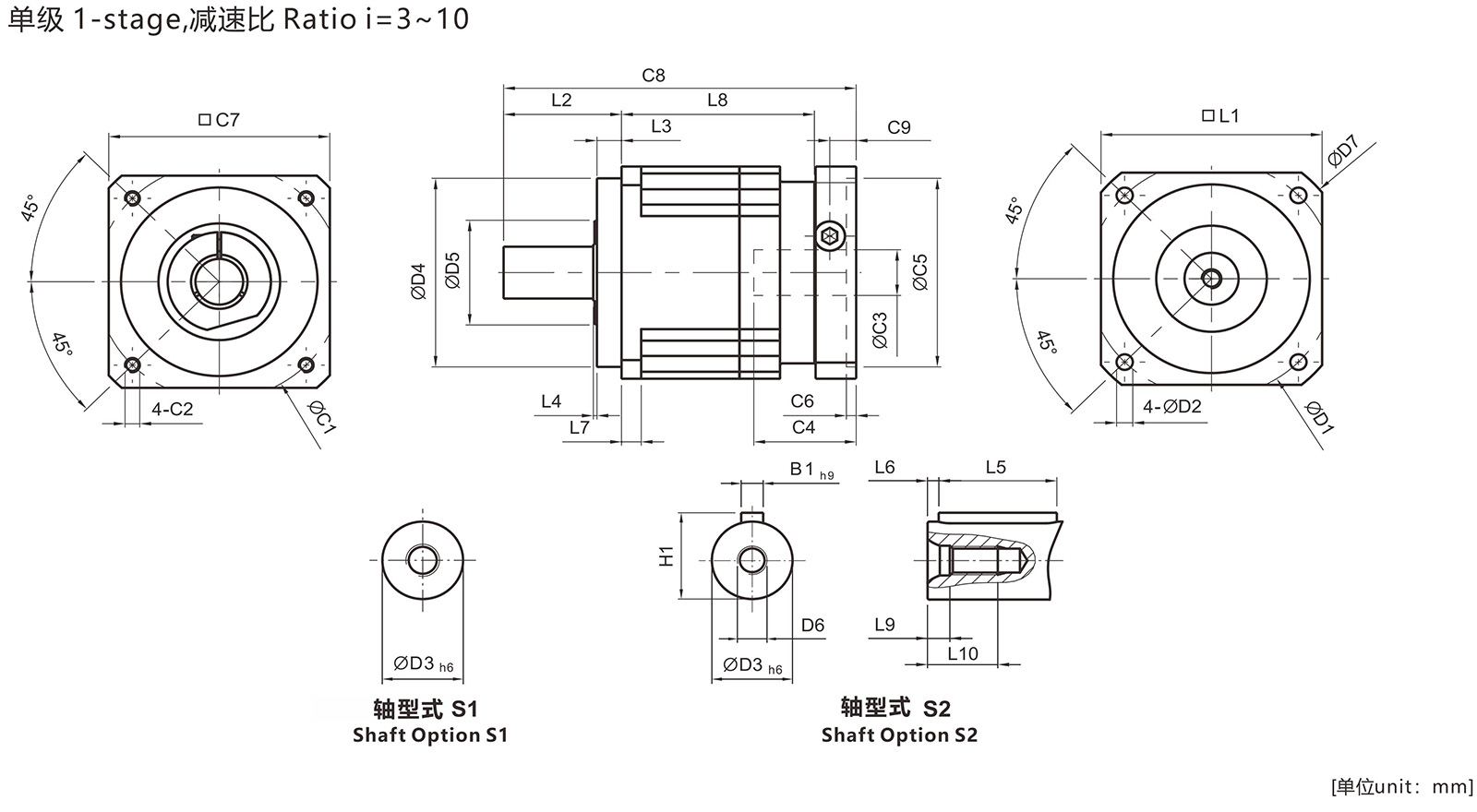

| Dimension | BAB042 | BAB060 | BAB090 | BAB115 | BAB142 | BAB180 | BAB220 |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 |

| D3 h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| D4 g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 |

| D6 | M4x0.7P | M5×0.8P | M8×1.25P | M12×1.75P | M16×2P | M20x2.5P | M20x2.5P |

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 |

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 |

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 |

| L5 | 16 | 25 | 32 | 40 | 65 | 70 | 90 |

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 |

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L8 | 31 | 61 | 78.5 | 102 | 104 | 154 | 163.5 |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 |

| L10 | 10 | 12.5 | 19 | 28 | 36 | 43 | 42 |

| C11 | 46 | 70 | 100 | 130 | 165 | 215 | 235 |

| C21 | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8X1.25Px25 | M10x1·5Px25 | M12x1.75Px28 | M12x1.75Px28 |

| C31 G7 | ≤11/≤122 | ≤14/≤16² | ≤19/≤24 | ≤32 | ≤38 | ≤48 | ≤55 |

| C41 | 25 | 34 | 40 | 50 | 60 | 85 | 116 |

| C51 G7 | 30 | 50 | 80 | 110 | 130 | 180 | 200 |

| C61 | 3.5 | 4 | 6 | 5 | 6 | 6 | 6 |

| C71 | 42 | 60 | 90 | 115 | 142 | 190 | 220 |

| C81 | 86.5 | 117 | 143.5 | 186.5 | 239 | 288 | 364.5 |

| C91 | 8.75 | 13.5 | 10.75 | 13 | 15 | 20.75 | 53 |

| B1 h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |

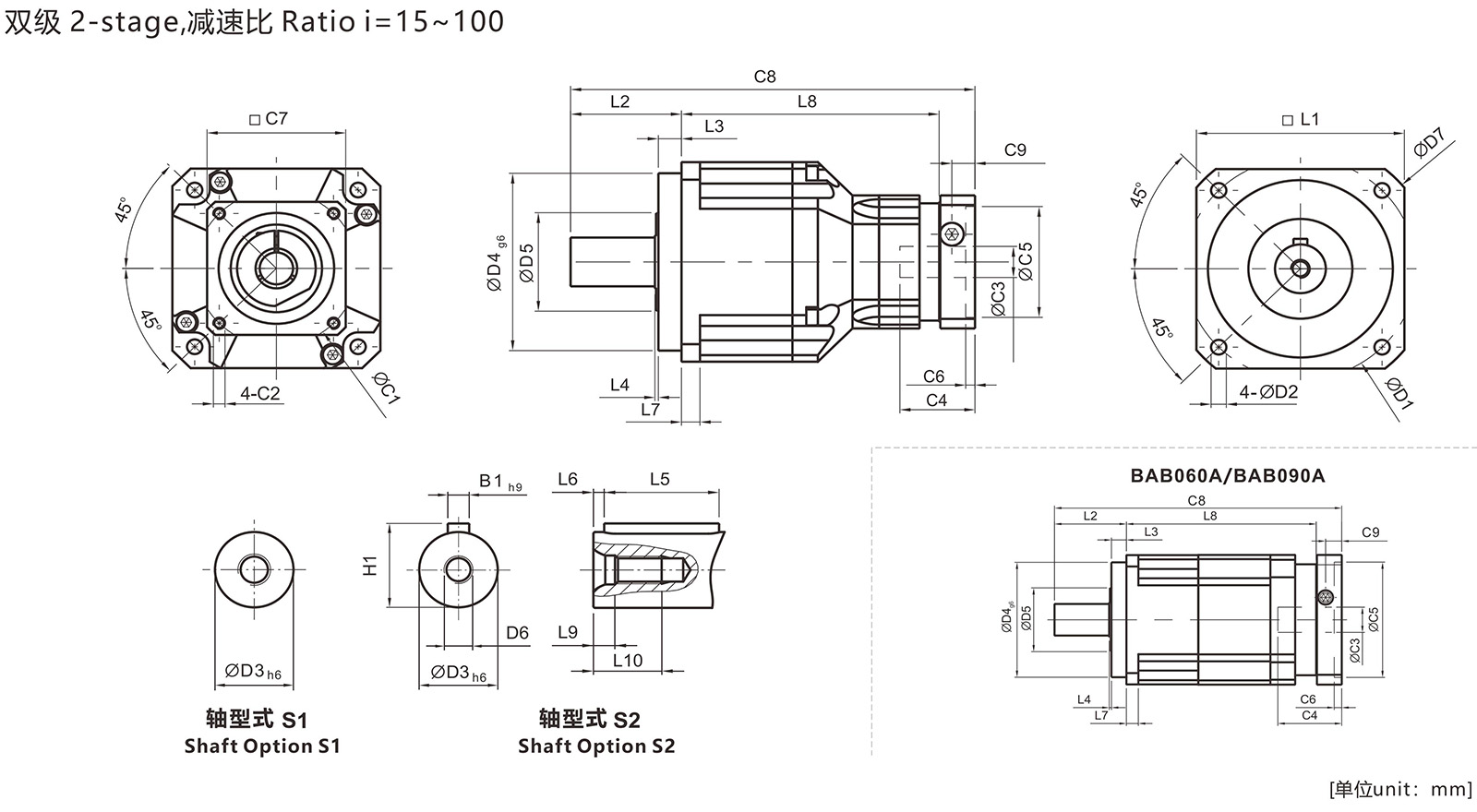

| Dimension | BAB042 | BAB060 | BAB060A | BAB090 | BAB090A | BAB115 | BAB142 | BAB180 | BAB220 | |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 | |||

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 | |||

| D3 h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 | |||

| D4 g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 | |||

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 | |||

| D6 | M4x0.7P | M5×0.8P | M8×1.25P | M12×1.75P | M16×2P | M20x2.5P | M20x2.5P | |||

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 | |||

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 | |||

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 | |||

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 | |||

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 | |||

| L5 | 16 | 25 | 32 | 40 | 65 | 70 | 90 | |||

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 | |||

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 | |||

| L8 | 58.5 | 72 | 98 | 111.5 | 126.5 | 143.5 | 176 | 209.5 | 248 | |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 | |||

| L10 | 10 | 12.5 | 19 | 28 | 36 | 42 | 42 | |||

| C11 | 46 | 46 | 70 | 70 | 100 | 100 | 130 | 165 | 215 | |

| C21 | M4x0.7Px10 | M4x0.7Px10 | M5x0.8Px12 | M5x0.8Px12 | M6x1Px12 | M6x1Px12 | M8x1.25Px25 | M10x1.5Px28 | M12x1.75Px28 | |

| C31 G7 | ≤11/≤12 | ≤11/≤12 | ≤14/≤16 |

≤14/15.875/≤16 |

≤19/≤24 | ≤19/≤24 | ≤32 | ≤38 | ≤48 | |

| C41 | 25 | 25 | 34 | 34 | 40 | 40 | 50 | 60 | 85 | |

| C51 G7 | 30 | 30 | 50 | 50 | 80 | 80 | 110 | 130 | 180 | |

| C61 | 3.5 | 3.5 | 4 | 6 | 4 | 4 | 5 | 6 | 6 | |

| C71 | 42 | 42 | 60 | 60 | 90 | 90 | 115 | 142 | 190 | |

| C81 | 114 | 138.5 | 154 | 178.5 | 191.5 | 225.5 | 292.5 | 337 | 415 | |

| C91 | 8.75 | 8.75 | 13.5 | 13.5 | 10.75 | 10.75 | 13 | 15 | 20.75 | |

| B1 h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 | |||

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 | |||