BABR Precision Planetary Gear Units

Reliability

● Spiral gears comfiguration adopted with an engage-ment ratio as twice as the common spur gears, features more smooth running condition low noise,high output torque and low back clearance.

● Gears are made of alloy metal with premium quality, applied with surface hardness treatment, grinded byhigh-precision grinder, offering great wear-resisting characteristic and impact resistance.

| Model NO | Stage | Ratio | BABR042 | BABR060 | BABR090 | BABR115 | BABR142 | BABR180 | BABR220 | ||||||

| (Mominal Output Torque Tzn) | Nm | 1 | 3 | 9 | 36 | 90 | 195 | 342 | 588 | 1,140 | |||||

| 4 | 12 | 48 | 120 | 260 | 520 | 1,040 | 1,680 | ||||||||

| 5 | 15 | 60 | 260 | 325 | 650 | 1.200 | 2,000 | ||||||||

| 6 | 18 | 55 | 325 | 310 | 600 | 1,100 | 1,900 | ||||||||

| 7 | 19 | 50 | 310 | 300 | 550 | 1,100 | 1,800 | ||||||||

| 8 | 17 | 45 | 120 | 260 | 500 | 1,000 | 1,600 | ||||||||

| 9 | 14 | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 10 | 14 | 60 | 150 | 325 | 90 | 1.200 | 2,000 | ||||||||

| 14 | - | 42 | 140 | 300 | 50 | 1,100 | 1,800 | ||||||||

| 20 | - | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 2 | 15 | 14 | - | - | - | - | - | - | |||||||

| 20 | 14 | - | - | - | - | - | - | ||||||||

| 25 | 15 | 60 | 150 | 325 | 650 | 1,200 | 2,000 | ||||||||

| 30 | 20 | 55 | 150 | 310 | 600 | 1,100 | 1,900 | ||||||||

| 35 | 19 | 50 | 140 | 300 | 550 | 1.100 | 1,800 | ||||||||

| 40 | 17 | 45 | 120 | 260 | 500 | 1,000 | 1,600 | ||||||||

| 45 | 14 | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 50 | 14 | 60 | 100 | 230 | 650 | 1,200 | 2,000 | ||||||||

| 60 | 20 | 55 | 150 | 310 | 600 | 1,100 | 1,900 | ||||||||

| 70 | 19 | 50 | 140 | 300 | 550 | 1.100 | 1,800 | ||||||||

| 80 | 17 | 45 | 120 | 260 | 500 | 1,000 | 1,600 | ||||||||

| 90 | 14 | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 100 | 14 | 40 | 150 | 325 | 650 | 1,200 | 2,000 | ||||||||

| 120 | - | - | 150 | 325 | 650 | 1,100 | 1,900 | ||||||||

| 140 | - | - | 140 | 300 | 550 | 1,100 | 1,800 | ||||||||

| 160 | - | - | 120 | 260 | 550 | 1,000 | 1,600 | ||||||||

| 180 | - | - | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 200 | - | - | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| (Emergency Stop Torque Tznor) | Nm | 1,2 | 3~200 | (3 Time of Mominal Output Torque) | |||||||||||

| (Nominal Input Speed N1N) | rpm | 1,2 | 3~200 | 5,000 | 5,000 | 4, 000 | 4, 000 | 3, 000 | 3, 000 | 2, 000 | |||||

| (Nominal Input Speed N1B) | rpm | 1,2 | 3~200 | 10,000 | 10,000 | 8, 000 | 8, 000 | 6, 000 | 6, 000 | 4, 000 | |||||

| (Micro Backiash PO) | arcmin | 1 | 3~20 | - | - | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | |||||

| 2 | 12~200 | - | - | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |||||||

| (Redduced Backlash P1) | arcmin | 1 | 3~20 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |||||

| 2 | 2~200 | ≤7 | <7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | |||||||

| (Standard Backlash P2) | arcmin | 1 | U | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | |||||

| 2 | 2~200 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | |||||||

| Torsion rigidity | Nm/arcnmin | 1,2 | 3~20 | 3 | 7 | 14 | 25 | 50 | 145 | 225 | |||||

| (Maximum bending moment M2kB) | Nm | 1,2 | 3~200 | 780 | 1,530 | 3, 250 | 6, 700 | 9, 400 | 14, 500 | 50, 000 | |||||

| (Allowable radial force F2aB) | N | 1,2 | 3~200 | 390 | 765 | 1, 625 | 3, 350 | 4, 700 | 7, 250 | 25, 000 | |||||

| (Servicelife) | hr | 1,2 | 3~200 | 20.000 | |||||||||||

| (Efficiency) | % | 1 | 3~20 | ≤95% | |||||||||||

| 2 | 12~200 | ≤92% | |||||||||||||

| (Weight) | kg | 1 | 3~20 | 0.9 | 2.1 | 6.4 | 13 | 24.5 | 51 | 83 | |||||

| 2 | 2~200 | 1.2 | 1.5 | 7.8 | 14.2 | 27.5 | 54 | 95 | |||||||

| (Operating Temp) | ℃ | 1,2 | 3~200 | 0°C+90°℃ | |||||||||||

| (Lubrication) | 1,2 | 3~200 | Synthetic lubrication oils | ||||||||||||

| (Degree of Gearbox protection) | 1,2 | 3~200 | |P65 | ||||||||||||

| (Mounting Position) | 1,2 | 3~200 | All directions | ||||||||||||

| Noise(n1=3000 rpmi=10, No load) | dB(A) | 1,2 | 3~200 | ≤61 | ≤63 | ≤65 | ≤68 | ≤70 | ≤72 | ≤74 | |||||

Product Detail

PIntroducing our new product, reducer series. The range is available in a variety of specifications, allowing customers to choose the product that best suits their needs. The reducer series includes 7 specifications: 042, 060, 090, 115, 142, 180 and 220, providing options for various applications.

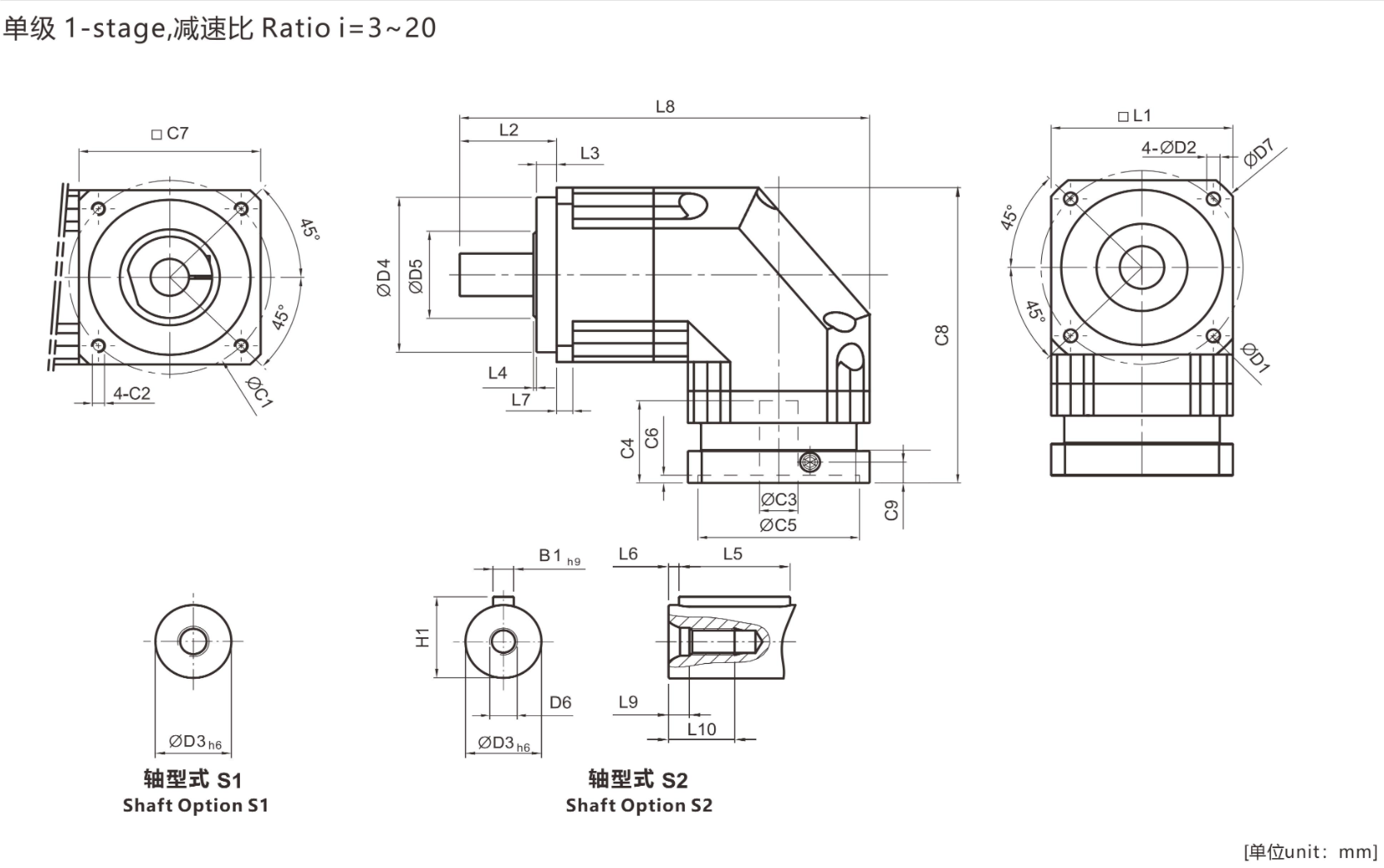

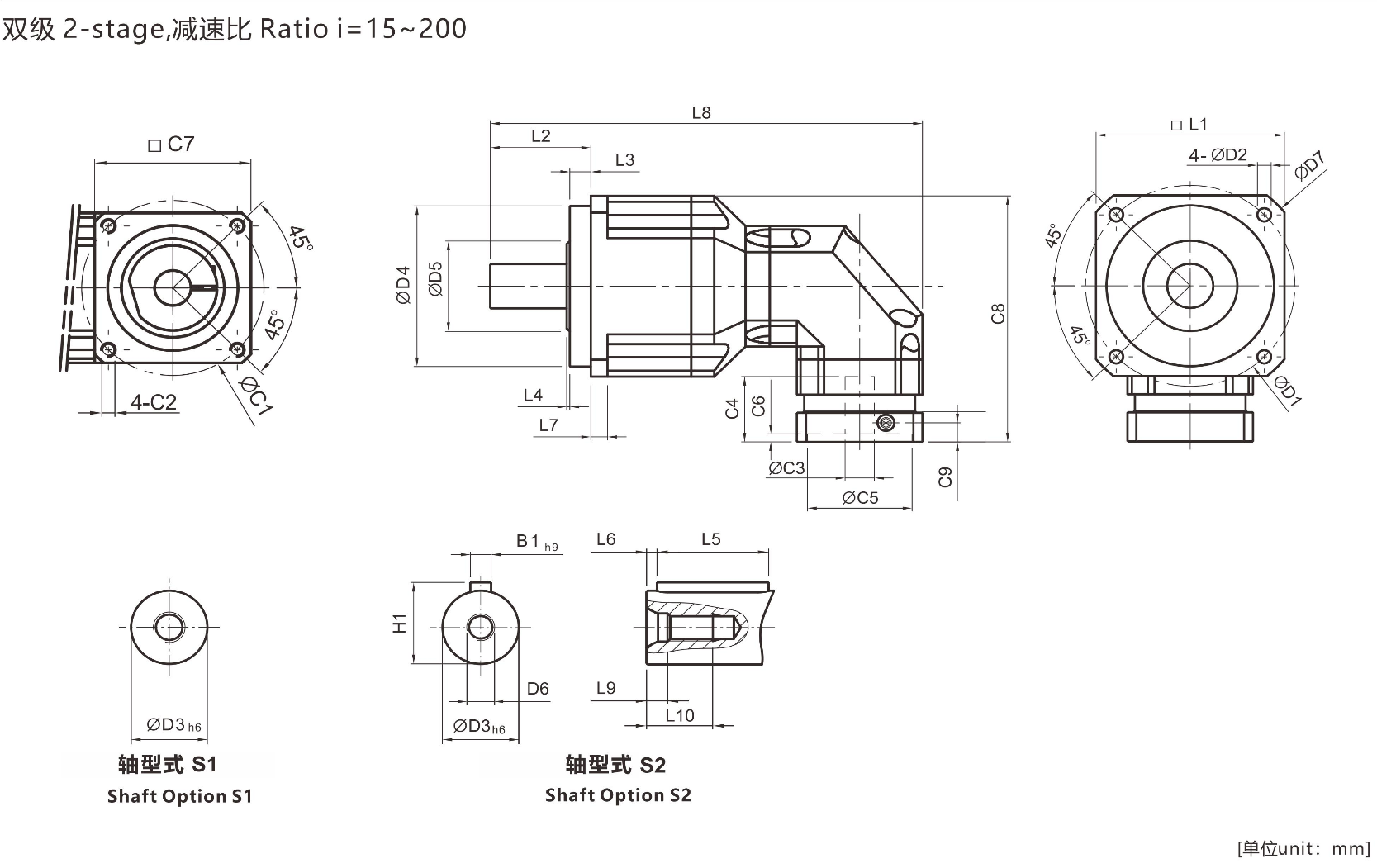

Our reducer series has a maximum rated output torque of 2000Nm and offers excellent performance. The single-stage reduction ratio range is from 3 to 20, ensuring precise control and efficient operation. For greater versatility, we also offer dual stages with reduction ratios ranging from 15 to 200.

One of the main features of our reducer range is its reliability. Adopting an integrated double support structure design to enhance rigidity and torque capabilities. The 90° output angle allows for flexible installation in tight spaces while offering a variety of transmission options.

Durability is of the utmost importance to us, which is why the gears in our reducer range are made from high-quality alloy materials. These gears are case-hardened and machined using high-precision gear grinders, giving them excellent wear resistance, impact resistance and toughness.

Whether you need precise control, efficient operation or reliable performance, our range of reducers can meet your needs. Trust our expertise and choose our range of reducers for your next project. Experience the difference in performance and reliability our products deliver.

Application

1. Aerospace field

2. Medical industry

3. Industrial robots, Industrial Automation, CNC machine tool manufacturing industry automotive industry, printing, agriculture, food industry, enviroment protection engineering, warehouse logistics industry.

| Dimension | BABR042 | BABR060 | BABR090 | BABR115 | BABR142 | BABR180 | BABR220 |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 |

| D3 h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| D4 g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 |

| D6 | M4x0.7P | M5x0.8P | M8x1.25P | M12x1.75P | M16x2P | M20x2.5P | M20x2.5P |

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 |

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 |

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 |

| L5 | 16 | 25 | 32 | 40 | 63 | 70 | 90 |

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 |

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L8 | 111.5 | 145 | 203 | 259 | 333 | 394 | 484 |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 |

| L10 | 10 | 12.5 | 19 | 28 | 36 | 42 | 42 |

| C11 | 46 | 70 | 100 | 130 | 165 | 215 | 235 |

| C2¹ | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8x1.25Px25 | M10x1.5Px25 | M12x1.75Px28 | M12x1.75Px28 |

| C3¹G7 | ≤11/≤12 | ≤14/≤16 | ≤19/≤24 | ≤32 | ≤38 | ≤48 | ≤55 |

| C41 | 25 | 34 | 40 | 50 | 60 | 85 | 116 |

| C5¹G7 | 30 | 50 | 80 | 110 | 130 | 180 | 200 |

| C6¹ | 3.5 | 4 | 6 | 5 | 6 | 6 | 6 |

| C71 | 42 | 60 | 90 | 115 | 142 | 190 | 220 |

| C8¹ | 90.5 | 111.5 | 152.5 | 191.5 | 235.5 | 303.5 | 378.5 |

| C9¹ | 8.75 | 13.5 | 10.75 | 13 | 15 | 20.75 | 53 |

| B1 h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |

| Dimension | BABR042 | BABR060 | BABR090 | BABR115 | BABR142 | BABR180 | BABR220 |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 |

| D3h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| D4g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 |

| D6 | M4x0.7P | M5x0.8P | M8x1.25P | M12x1.75P | M16x2P | M20x2.5P | M20x2.5P |

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 |

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 |

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 |

| L5 | 16 | 25 | 32 | 40 | 63 | 70 | 90 |

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 |

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L8 | 139 | 163.5 | 206.5 | 285 | 365 | 431 | 521 |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 |

| L10 | 100 | 12.5 | 19 | 28 | 36 | 42 | 42 |

| C11 | 46 | 46 | 70 | 100 | 130 | 165 | 215 |

| C2¹ | M4x0.7Px10 | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8x1.25Px25 | M10x1.5Px28 | M12x1.75Px28 |

| C3¹G7 | ≤11/≤12 | ≤11/≤12 | ≤14/≤15.875/≤16 | ≤19/≤24 | ≤32 | ≤38 | ≤48 |

| C41 | 25 | 25 | 34 | 40 | 50 | 60 | 85 |

| C5¹G7 | 30 | 30 | 50 | 80 | 110 | 130 | 180 |

| C61 | 3.5 | 3.5 | 4 | 6 | 5 | 6 | 6 |

| C71 | 42 | 42 | 60 | 90 | 115 | 142 | 190 |

| C81 | 90.5 | 99.5 | 126.5 | 165 | 205 | 254.5 | 323.5 |

| C91 | 8.75 | 8.75 | 13.5 | 10.75 | 13 | 15 | 20.75 |

| B1 h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |