BAD Precision Planetary Gear Units

Reliability

● Spiral gears comfiguration adopted with an engage-ment ratio over 33%, features more smooth running condition low noise, high output torque and low back clearance.

● Gears are made of alloy metal with premium quality, applied with surface hardness treatment, grinded by high-precision grinder, offering great wear-resisting characteristic and impact resistance.

| Model NO | Stage | Ratio | BAD047 | BAD064 | BAD090 | BAD110 | BAD140 | BAD200 | BAD255 | |

| (Mominal Output Torque Tzn) | Nm | 1 | 4 | 19 | 48 | 130 | 270 | 560 | 1100 | 1700 |

| 5 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 6 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 7 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 8 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 10 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 2 | 20 | 19 | 48 | 130 | 270 | 560 | 1100 | 1700 | ||

| 25 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 35 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 19 | 48 | 130 | 270 | 560 | 1100 | 1700 | |||

| 50 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 70 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 100 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 16 | 19 | 48 | 130 | 270 | 560 | 1100 | 1700 | |||

| 21 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 31 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 61 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 91 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| (Emergency Stop Torque Tznor) | Nm | 1,2 | 4~100 | (3 Times of Mominal Output Torque) | ||||||

| (Nominal Input Speed N1N) | rpm | 1,2 | 4~100 | 5,000 | 5, 000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| (Nominal Input Speed N1B) | rpm | 1,2 | 4~100 | 10,000 | 10, 000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| (Micro Backiash PO) | arcmin | 1 | 4~10 | - | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 20~100 | - | - | - | S3 | ≤3 | S3 | S3 | ||

| (Redduced Backlash P1) | arcmin | 1 | 4~10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | S3 |

| 2 | 20~100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| (Standard Backlash P2) | arcmin | 1 | 4~10 | ≤5 | ≤5 | S5 | ≤5 | ≤5 | S5 | ≤5 |

| 2 | 20~100 | ≤7 | S7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| (Efficiency) | % | 1 | 4~10 | ≤97% | ||||||

| 2 | 20~100 | ≤94% | ||||||||

| (Weight) | kg | 1 | 4~10 | 0.7 | 1.2 | 3.0 | 5.6 | 11.9 | 31.6 | 56.1 |

| 2 | 20~100 | 1.0 | 1.6 | 3.7 | 7.3 | 15.9 | 34.9 | 70.4 | ||

| 16~91 | 1.0 | 1.4 | 3.5 | 6.5 | 15.5 | 34.2 | 67.2 | |||

| (Operating Temp) | ℃ | 2 | 4~100 | -10°C~90°C | ||||||

| (Lubrication) | Synthetic lubrication oils | |||||||||

| (Degree of Gearbox protection) | 1,2 | 4~100 | IP65 | |||||||

| (Mounting Position) | 1,2 | 4~100 | All directions | |||||||

| Noise(n1=3000 rpmi=10, No load) | dB(A) | 1,2 | 4~100 | ≤56 | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 |

Product Detail

Introducing our latest product, multi-functional high-performance reducer. Designed to meet a variety of requirements, the product is available in 7 different types of reducers, including 047, 064, 090, 110, 140, 200 and 255. No matter what your specific needs are, you can choose the perfect reducer from our wide range of options.

When it comes to performance, our reducers don’t disappoint. The maximum rated output torque is 2000Nm, which can easily handle the most demanding tasks. Available single-stage reduction ratios are 4, 5, 6, 7, 8 and 10, allowing for precise control and customization. In addition, our products also feature dual levels with ratios ranging from 20 to 100.

Reliability is always our top priority and our reducers are no exception. Utilizing the helical gear design, we increased the tooth mesh ratio to over 33%. This not only ensures smooth operation but also produces low noise. Additionally, high output torque and low backlash make our reducers a reliable choice for any application.

We understand the importance of durability for any product, which is why our reducers are designed with high-quality alloy materials. The gears are surface hardened and precision ground using state-of-the-art gear grinding machines. This makes them extremely wear-resistant, impact-resistant and tough, guaranteeing a long service life even with heavy use.

Whether you need a reducer for industrial machinery, robotics, automotive systems or any other application, our products can meet your needs. With their wide selection, outstanding performance, reliability and durability, our reducers are sure to exceed your expectations.

Invest in our reducers and experience the difference in performance and reliability. We believe our products can not only meet but exceed your requirements. Don’t settle for average, choose the best with our top gear reducers.

Application

1. Aerospace field

2. Medical industry

3. Industrial robots, Industrial Automation, CNC machine tool manufacturing industry automotive industry, printing, agriculture, food industry, enviroment protection engineering, warehouse logistics industry.

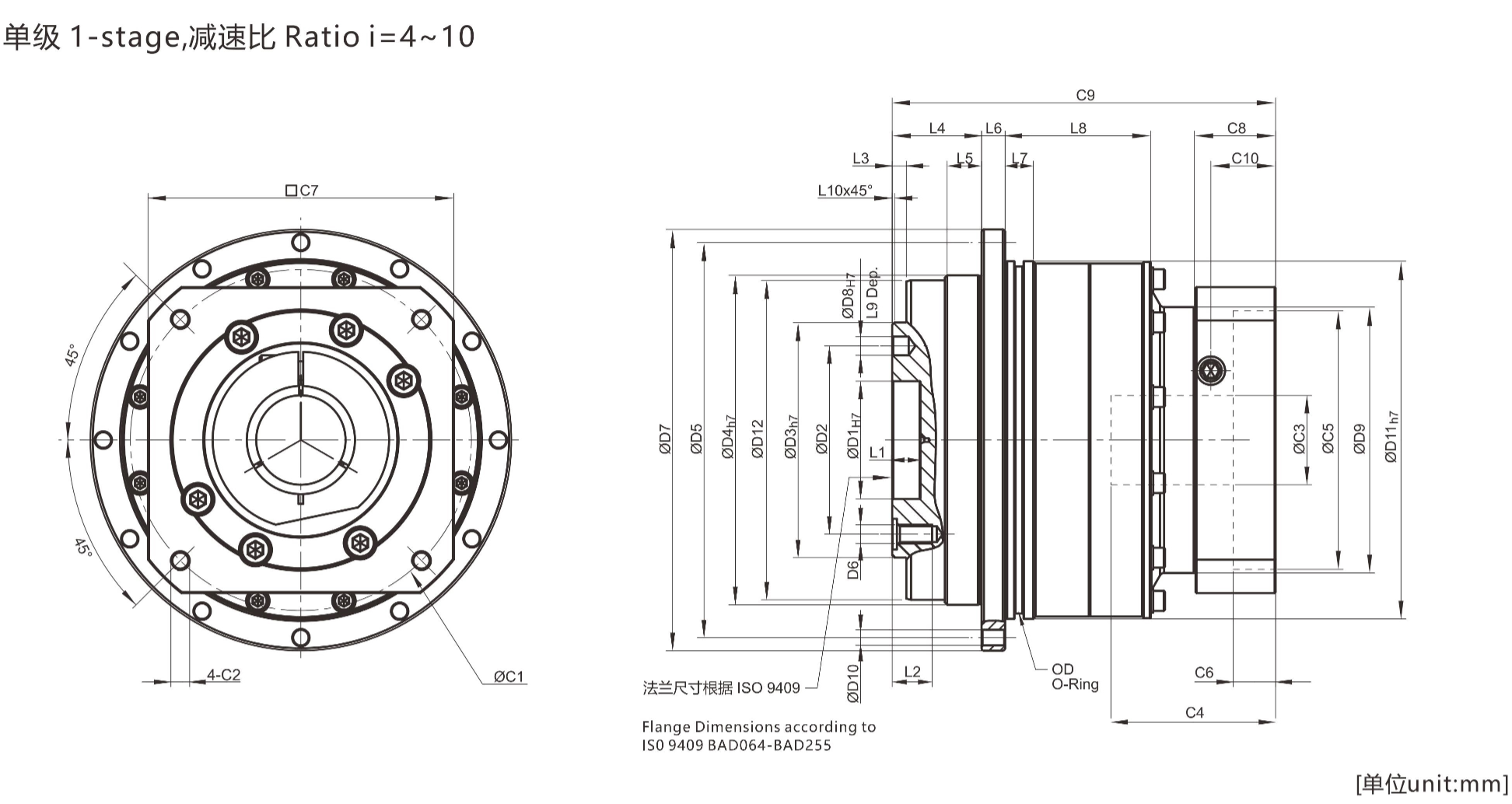

| Dimension | BAD047 | BAD064 | BAD090 | BAD110 | BAD140 | BAD200 | BAD255 |

| D1 H7 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

| D2 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

| D3 h7 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

| D4 h7 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

| D5 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

| D6 | 4xM3x0.5P | 7x M5x0.8P | 7x M6x1P | 11xM6x1P | 11xM8x1.25P | 11xM10x1.5P | 12xM16x2P |

| D7 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

| D8 H7 | 3 | 5 | 6 | 6 | 8 | 10 | 12 |

| D9 | 45.5 | 55 | 77 | 90 | 113 | 138 | 175 |

| D10 | 8×3.4 | 8×4.5 | 8×5.5 | 8×5.5 | 12×6.6 | 12×9 | 16×13.5 |

| D11 h7 | 60 | 70 | 95 | 120 | 152 | 212 | 255 |

| D12 | 46.2 | 63.2 | 89.2 | 109.2 | 139.2 | 199.2 | 254.2 |

| L1 | 4 | 8 | 12 | 12 | 12 | 16 | 20 |

| L2 | 6.5 | 8 | 13.5 | 13.5 | 17 | 22.5 | 30.5 |

| L3 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

| L4 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

| L5 | 7 | 7 | 10 | 10 | 14.6 | 15 | 20 |

| L6 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

| L7 | 5 | 7.7 | 8 | 10 | 12 | 15 | 20 |

| L8 | 18.5 | 28.5 | 27 | 37 | 62 | 69.5 | 82 |

| L9 | 4 | 6 | 7 | 7 | 7 | 10 | 10 |

| L10 | 0.5 | 0.5 | |||||

| C11 | 46 | 70 | 100 | 130 | 165 | 215 | 235 |

| C21 | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8x1.25Px25 | M10x1.5Px25 | M12x1.75Px28 | M12x1.75Px28 |

| C31G7 | ≤11/≤12² | ≤14/<162 | ≤191≤24 | ≤32 | ≤38 | ≤48 | ≤55 |

| C41 | 30 | 34 | 40 | 50 | 60 | 85 | 116 |

| C51G7 | 30 | 50 | 80 | 110 | 130 | 180 | 200 |

| C61 | 3.5 | 8 | 4 | 5 | 6 | 6 | 6 |

| C71 | 48 | 60 | 90 | 115 | 142 | 190 | 220 |

| C81 | 19.5 | 19 | 17 | 19.5 | 22.5 | 29 | 63 |

| C91 | 70 | 82.5 | 99.5 | 121.5 | 151 | 199.5 | 256.5 |

| C101 | 13.25 | 13.5 | 10.75 | 13 | 15 | 20.75 | 53.5 |

| OD | 56×2 | 66×2 | 90×3 | 110×3 | 145×3 | 200×5 | 238×5 |

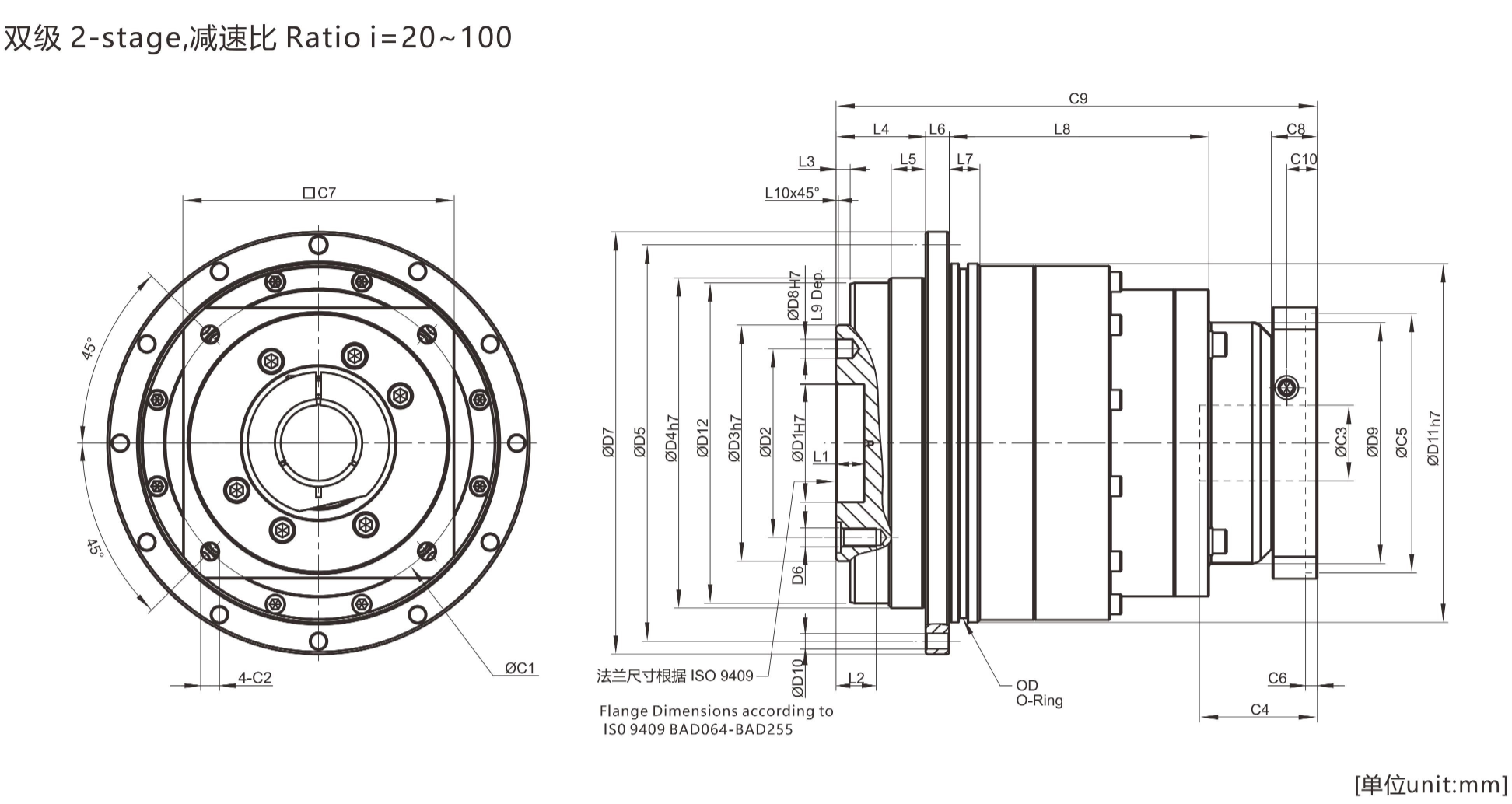

| Dimension | BAD047 | BAD064 | BAD090 | BAD110 | BAD140 | BAD200 | BAD255 |

| D1 H7 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

| D2 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

| D3 h7 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

| D4 h7 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

| D5 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

| D6 | 4xM3x0.5P | 7x M5x0.8P | 7x M6x1P | 11xM6x1P | 11xM8x1.25P | 11xM10x1.5P | 12xM16x2P |

| D7 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

| D8 H7 | 3 | 5 | 6 | 6 | 8 | 10 | 12 |

| D9 | 45.5 | 55 | 77 | 90 | 113 | 138 | 175 |

| D10 | 8×3.4 | 8×4.5 | 8×5.5 | 8×5.5 | 12×6.6 | 12×9 | 16×13.5 |

| D11 h7 | 60 | 70 | 95 | 120 | 152 | 212 | 255 |

| D12 | 46.2 | 63.2 | 89.2 | 109.2 | 139.2 | 199.2 | 254.2 |

| L1 | 4 | 8 | 12 | 12 | 12 | 16 | 20 |

| L2 | 6.5 | 8 | 13.5 | 13.5 | 17 | 22.5 | 30.5 |

| L3 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

| L4 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

| L5 | 7 | 7 | 10 | 10 | 14.6 | 15 | 20 |

| L6 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

| L7 | 5 | 7.7 | 8 | 10 | 12 | 15 | 20 |

| L8 | 18.5 | 28.5 | 27 | 37 | 62 | 69.5 | 82 |

| L9 | 4 | 6 | 7 | 7 | 7 | 10 | 10 |

| L10 | 0.5 | 0.5 | |||||

| C11 | 46 | 70 | 100 | 130 | 165 | 215 | 235 |

| C21 | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8x1.25Px25 | M10x1.5Px25 | M12x1.75Px28 | M12x1.75Px28 |

| C31G7 | ≤11/≤12² | ≤14/<16 | ≤191≤24 | ≤32 | ≤38 | ≤48 | ≤55 |

| C41 | 30 | 34 | 40 | 50 | 60 | 85 | 116 |

| C51G7 | 30 | 50 | 80 | 110 | 130 | 180 | 200 |

| C61 | 3.5 | 8 | 4 | 5 | 6 | 6 | 6 |

| C71 | 48 | 60 | 90 | 115 | 142 | 190 | 220 |

| C81 | 19.5 | 19 | 17 | 19.5 | 22.5 | 29 | 63 |

| C91 | 70 | 82.5 | 99.5 | 121.5 | 151 | 199.5 | 256.5 |

| C101 | 13.25 | 13.5 | 10.75 | 13 | 15 | 20.75 | 53.5 |

| OD | 56×2 | 66×2 | 90×3 | 110×3 | 145×3 | 200×5 | 238×5 |