DRV Combination Of Double Worm Gearboxes

Product specifications

Our modular combination reducers are available in a variety of power options, from 0.06 to 1.5kW. With such a wide power range, customers can choose the product that best suits their specific application. Additionally, these reducers deliver a maximum output torque of 3000Nm, ensuring they can handle the most demanding industrial tasks.

Unparalleled performance

One of the main advantages of our modular combination gearboxes is their outstanding performance. By modularly combining DRVs, customers have the flexibility to choose the ratio that best suits their needs, ranging from 100 to 5000. This ensures unparalleled precision and efficiency in power transmission.

Reliability guaranteed

We know that when it comes to industrial machinery, reliability is crucial. That’s why we carefully engineer our modular combination reducers using the highest quality materials to ensure their longevity and durability.

Our reducer box is made of high-quality aluminum alloy base 025-090, which is rust-proof and corrosion-resistant. For bases 110-150 we use cast iron, which is renowned for its reliability and durability. This ensures our reducers can withstand the harshest operating conditions, giving our customers peace of mind.

Additionally, we take great pride in the materials used to restore parts. The worm is made of high-quality alloy material and undergoes surface hardening treatment to improve its strength and service life. The tooth surface hardness of our reducer is 56-62HRC, which provides excellent performance and wear resistance.

In addition, the worm gear is made of high-quality, wear-resistant tin bronze, further enhancing the reliability and durability of our reducers. This ensures smooth and efficient power transmission while reducing the risk of wear.

in conclusion

Our modular combination reducers offer an unparalleled combination of versatility, performance and reliability. With a range of basic specifications and superior features such as variable speed, high torque output and durable construction, our reducers are the perfect solution for a variety of industrial applications.

Invest in our modular combination reducers and experience the power of innovation and customization. Trust our commitment to quality and reliability. Contact us today to learn more about how our reducers can transform your industrial machinery.

Application

Screw feeders for light materials, fans, assembly lines, conveyor belts for light materials, small mixers, lifts, cleaning machines, fillers, control machines.

Winding devices, woodworking machine feeders, goods lifts, balancers, threading machines, medium mixers, conveyor belts for heavy materials, winches, sliding doors, fertilize scrapers, packing machines, concrete mixers, crane mechanisms, milling cutters, folding machines, gear pumps.

Mixers for heavy materials, shears, presses, centrifuges, rotating supports, winches and lifts for heavy materials, grinding lathes, stone mills, bucket elevators, drilling machines, hammer mills, cam presses, folding machines, turntables, tumbling barrels, vibrators, shredders.

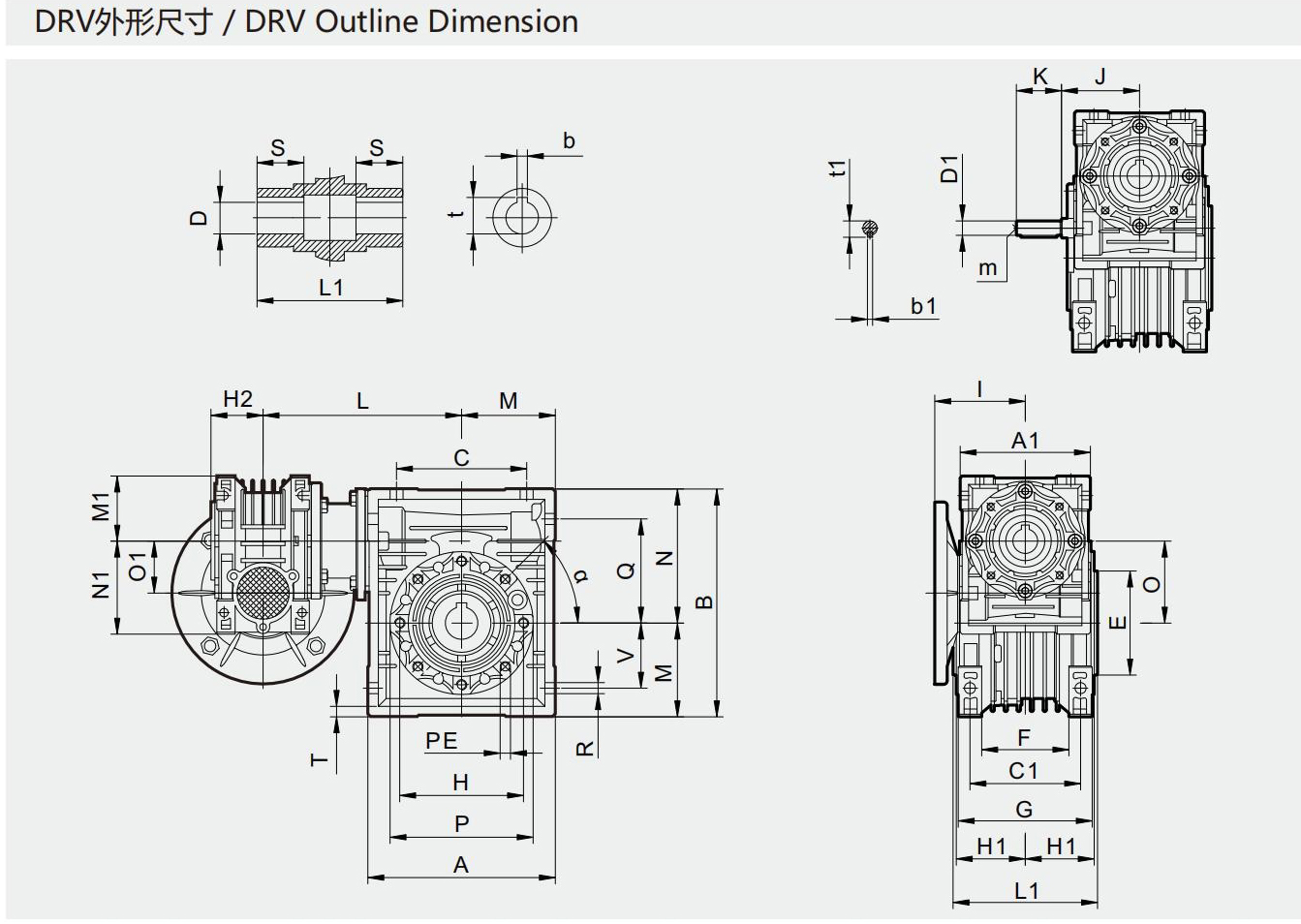

| DRV | A | A1 | B | C | C1 | D(H8) | D1(j6) | E(h8) | F | G | H | H1 | H2 | I | J | K | L | L1 | M | M1 |

| 025/030 | 80 | 70 | 97 | 54 | 44 | 14 | - | 55 | 32 | 56 | 65 | 29 | 22.5 | 45 | - | - | 100 | 63 | 40 | 35 |

| 025/040 | 100 | 70 | 121.5 | 70 | 60 | 18(19) | - | 60 | 43 | 71 | 75 | 36.5 | 22.5 | 45 | - | - | 115 | 78 | 50 | 35 |

| 030/040 | 100 | 80 | 121.5 | 70 | 60 | 18(19) | 9 | 60 | 43 | 71 | 75 | 36.5 | 29 | 55 | 51 | 20 | 120 | 78 | 50 | 40 |

| 030/050 | 120 | 80 | 144 | 80 | 70 | 25(24) | 9 | 70 | 49 | 85 | 85 | 43.5 | 29 | 55 | 51 | 20 | 130 | 92 | 60 | 40 |

| 030/063 | 144 | 80 | 174 | 100 | 85 | 25(28) | 9 | 80 | 67 | 103 | 95 | 53 | 29 | 55 | 51 | 20 | 145 | 112 | 72 | 40 |

| 040/075 | 172 | 100 | 205 | 120 | 90 | 28(35) | 11 | 95 | 72 | 112 | 115 | 57 | 36.5 | 70 | 60 | 23 | 165 | 120 | 86 | 50 |

| 040/090 | 206 | 100 | 238 | 140 | 00 | 35(38) | 11 | 110 | 74 | 130 | 130 | 67 | 36.5 | 70 | 60 | 23 | 182 | 140 | 103 | 50 |

| 050/110 | 255 | 120 | 295 | 170 | 115 | 42 | 14 | 130 | - | 144 | 165 | 74 | 43.5 | 80 | 74 | 30 | 225 | 155 | 127.5 | 60 |

| 063/130 | 293 | 144 | 335 | 200 | 120 | 45 | 19 | 180 | - | 155 | 215 | 81 | 53 | 95 | 90 | 40 | 245 | 170 | 146.5 | 72 |

| 063/150 | 340 | 144 | 400 | 240 | 45 | 50 | 19 | 180 | - | 185 | 215 | 96 | 53 | 95 | 90 | 40 | 275 | 200 | 170 | 72 |

| DRV | N | N1 | O | 01 | P | Q | R | S | T | V | PE | a | b | b1 | t | t1 | m | Kg |

| 025/030 | 57 | 48 | 30 | 25 | 75 | 44 | 6.5 | 21 | 5.5 | 27 | M6×10(n=4) | 0° | 5 | - | 16.3 | - | - | 1.9 |

| 025/040 | 71.5 | 48 | 40 | 25 | 87 | 55 | 6.5 | 26 | 6.5 | 35 | M6×10(n=4) | 45° | 6 | - | 20.8(21.8) | - | - | 3 |

| 030/040 | 71.5 | 57 | 40 | 30 | 87 | 55 | 6.5 | 26 | 6.5 | 35 | M6×10(n=4) | 45° | 6(6) | 3 | 20.8(21.8) | 10.2 | - | 3.65 |

| 030/050 | 84 | 57 | 50 | 30 | 100 | 64 | 8.5 | 30 | 40 | M8×10(n=4) | 45° | 8(8) | 3 | 28.3(27.3) | 10.2 | - | 4.85 | |

| 030/063 | 102 | 57 | 63 | 30 | 110 | 80 | 8.5 | 36 | 8 | 50 | M8×14(n=8) | 45° | 8(8) | 3 | 28.3(31.3) | 10.2 | - | 6.95 |

| 040/075 | 119 | 71.5 | 75 | 40 | 140 | 93 | 11 | 40 | 10 | 60 | M8×14(n=8) | 45° | 8(10) | 4 | 31.3(38.3) | 12.5 | - | 11.1 |

| 040/090 | 135 | 71.5 | 90 | 40 | 160 | 02 | 13 | 45 | 11 | 70 | M10×18(n=8) | 45° | 10 | 4 | 38.3(41.3) | 12.5 | - | 14.3 |

| 050/110 | 167.5 | 84 | 110 | 50 | 200 | 125 | 14 | 50 | 14 | 85 | M10×18(n=8) | 45° | 12 | 5 | 45.3 | 16 | - | 46 |

| 063/130 | 187.5 | 102 | 13C | 63 | 250 | 140 | 16 | 60 | 15 | 100 | M12×21(n=8) | 45° | 14 | 6 | 48.8 | 21.5 | M6 | 59.6 |

| 063/150 | 230 | 102 | 150 | 63 | 250 | 180 | 18 | 72.5 | 18 | 120 | M12×21(n=8) | 45° | 14 | 6 | 53.8 | 21.5 | M6 | 96.7 |