NRV Input Shaft Worm Gearbox

Product Detail

We leave no stone unturned when it comes to reliability. The cabinet is available in a variety of sizes and is made of high-quality aluminum alloy (025 to 090) to ensure durability and rust resistance. For larger models (110 to 150) we use cast iron construction for increased strength and longevity, making our reducers a reliable choice in even the most demanding environments.

The worm component is a key component of the reducer. It is made of high-quality alloy materials and has undergone surface hardening treatment. Our reducer tooth surface hardness is 56-62 HRC, which provides excellent impact resistance and ensures smooth and efficient operation.

In addition, the worm gear is made of high-quality, wear-resistant tin bronze, which is also critical for optimal performance. This material selection ensures wear resistance, minimizes maintenance and extends the service life of the reducer. You can rely on our reducers for long-term, consistent, trouble-free operation.

In addition to outstanding performance and reliability, our reducers are available in a flexible choice of ten different base sizes, including 025, 030, 040, 050, 063, 075, 090, 110, 130 and 150. This allows you to customize your selection, ensuring a perfect match to your specific requirements.

Whether you need a reducer for industrial machinery, automation systems or any other application where power transmission is critical, our versatile product range will meet your needs. Backed by our commitment to quality and customer satisfaction, our reducers are built to withstand the most demanding conditions and deliver unparalleled performance.

In summary, our reducers offer a seamless combination of power, reliability and flexibility. With a range of available options, you can choose the perfect reducer to suit your specific needs. Rely on our superior manufacturing quality, high-performance specifications and impeccable reliability to enhance your operations and increase overall productivity. Invest in our reducers today and experience the difference they can make for your business.

Application

Screw feeders for light materials, fans, assembly lines, conveyor belts for light materials, small mixers, lifts, cleaning machines, fillers, control machines.

Winding devices, woodworking machine feeders, goods lifts, balancers, threading machines, medium mixers, conveyor belts for heavy materials, winches, sliding doors, fertilize scrapers, packing machines, concrete mixers, crane mechanisms, milling cutters, folding machines, gear pumps.

Mixers for heavy materials, shears, presses, centrifuges, rotating supports, winches and lifts for heavy materials, grinding lathes, stone mills, bucket elevators, drilling machines, hammer mills, cam presses, folding machines, turntables, tumbling barrels, vibrators, shredders.

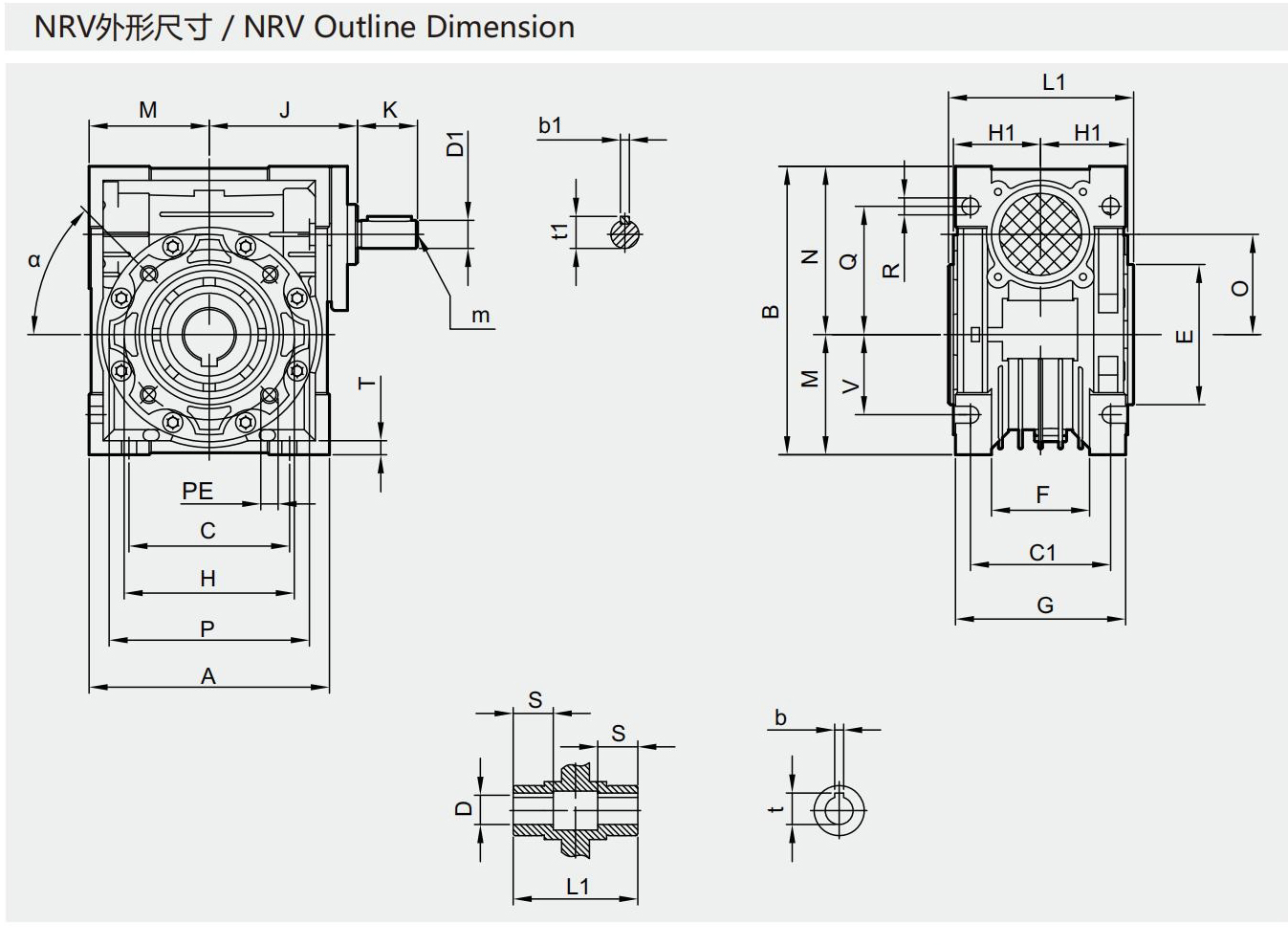

| NRV | A | B | C | C1 | D(H8) | D1(j6) | E(h8) | F | G | H | H1 | J | K | L1 | M | N | O |

| 030 | 80 | 97 | 54 | 44 | 14 | 9 | 55 | 32 | 56 | 65 | 29 | 51 | 20 | 63 | 40 | 57 | 30 |

| 040 | 100 | 121.5 | 70 | 60 | 18(19) | 11 | 60 | 43 | 71 | 75 | 36.5 | 60 | 23 | 78 | 50 | 71.5 | 40 |

| 050 | 120 | 144 | 80 | 70 | 25(24) | 14 | 70 | 49 | 85 | 85 | 43.5 | 74 | 30 | 92 | 60 | 84 | 50 |

| 063 | 144 | 174 | 100 | 85 | 25(28) | 19 | 80 | 67 | 103 | 95 | 53 | 90 | 40 | 112 | 72 | 102 | 63 |

| 075 | 172 | 205 | 120 | 90 | 28(35) | 24 | 95 | 72 | 112 | 115 | 57 | 105 | 50 | 120 | 86 | 119 | 75 |

| 090 | 206 | 238 | 140 | 100 | 35(38) | 24 | 110 | 74 | 130 | 130 | 67 | 125 | 50 | 140 | 103 | 135 | 90 |

| 110 | 255 | 295 | 170 | 115 | 42 | 28 | 130 | - | 144 | 165 | 74 | 142 | 60 | 155 | 127.5 | 167.5 | 110 |

| 130 | 293 | 335 | 200 | 120 | 45 | 30 | 180 | - | 155 | 215 | 81 | 162 | 80 | 170 | 146.5 | 187.5 | 130 |

| 150 | 340 | 400 | 240 | 145 | 50 | 35 | 180 | - | 185 | 215 | 96 | 195 | 80 | 200 | 170 | 230 | 150 |