PC Gear Units

Reliability

● Housing: die-case aluminium alloy, they made by the horizontal machining center in one-time-molding, ensures the accuracy and tolerancy of shape and position

● The gears are hard surface gear, made of high quality alloy, treated by surface hardening, and produced by high-precision grinding machine

| PCGEARUNITS | |||||||||||

| RV | PC063 | PC071 | PC080 | PC090 | |||||||

| IEC | 105/11 | 105/14 | 120/14 | 120/19 | 160/19 | 160/24 | 160/28 | 160/19 | 160/24 | 160/28 | |

| i=2.93 | i=2.93 | i=2.94 | i=2.94 | i=3 | i=3 | i=3 | i=2.45 | i=2.45 | i=2.45 | ||

| 040 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 050 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 063 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 075 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 090 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 110 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 130 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

Product Detail

Our product line includes four types of reducers, each with a different basic specification – 063, 071, 080 and 090. This enables our customers to select the reducer that best suits their unique needs, ensuring optimal efficiency and performance.

In terms of power consumption, our reducers provide power ranging from 0.09 to 1.5kW. This flexibility enables you to select the appropriate power level required for your specific application and avoid unnecessary waste of energy.

In addition, our reducers have a maximum output torque of 24Nm, ensuring they can handle the most demanding tasks. Whether it’s heavy duty or high-speed applications, our reducers rise to the challenge with ease.

What sets our reducers apart is their compatibility with RV systems, adding extra versatility to your power transmission solution. Our reducers integrate seamlessly with RV systems, offering a wide speed ratio range from 2.45 to 300. This allows you to easily achieve the speed and precision you need in your operations.

When it comes to reliability, our reducers are second to none. The cabinet is made of high-quality aluminum alloy, which has excellent durability and does not rust. The use of vertical machining centers during the manufacturing process ensures high precision, maintaining the tightest shape and position tolerances.

To further improve reliability and durability, the gears in our reducers are made of high-quality alloy materials. In addition, the gears are case-hardened and carefully machined using a high-precision gear grinder. The result is a hard-faced gear that can withstand the harshest operating conditions.

In short, our reducers are the epitome of efficiency, reliability and durability. Their seamless compatibility with RV systems, wide ratio range and rugged construction make them the ultimate choice for power transmission solutions. Don’t compromise on performance – choose our reducers and experience the difference firsthand.

Application

Screw feeders for light materials, fans, assembly lines, conveyor belts for light materials, small mixers, lifts, cleaning machines, fillers, control machines.

Winding devices, woodworking machine feeders, goods lifts, balancers, threading machines, medium mixers, conveyor belts for heavy materials, winches, sliding doors, fertilize scrapers, packing machines, concrete mixers, crane mechanisms, milling cutters, folding machines, gear pumps.

Mixers for heavy materials, shears, presses, centrifuges, rotating supports, winches and lifts for heavy materials, grinding lathes, stone mills, bucket elevators, drilling machines, hammer mills, cam presses, folding machines, turntables, tumbling barrels, vibrators, shredders.

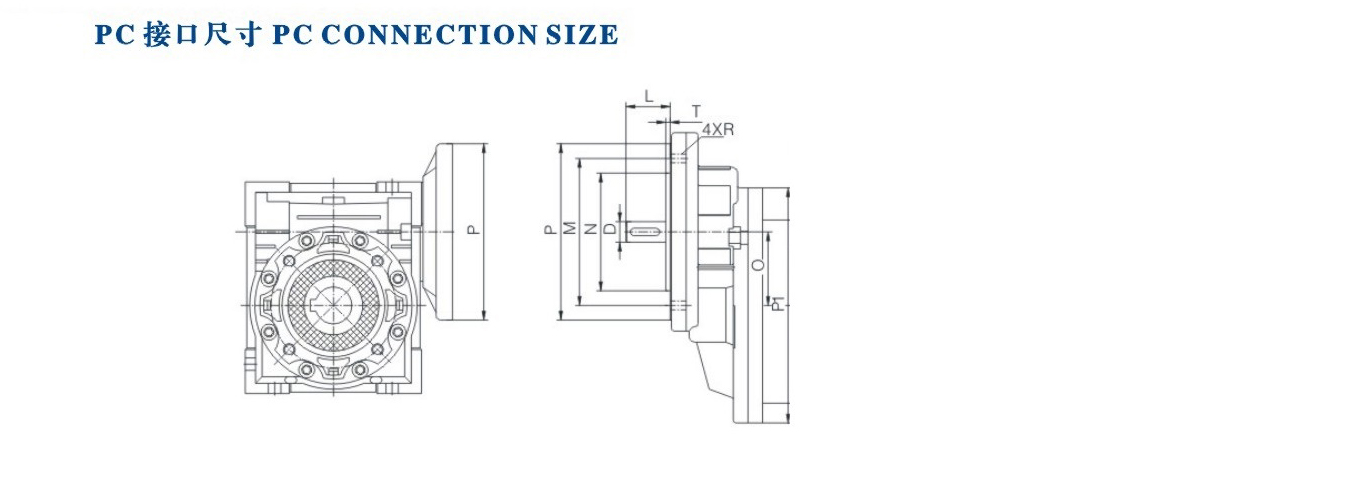

| TYPE | D(k6) | N(j6) | M | O | P | P1 | R | T | L |

| PC063 | 11(14) | 70 | 85 | 40 | 105 | 140(63B5) | m6 | 3 | 23 |

| PC071 | 14(19) | 80 | 100 | 48 | 120 | 160(71B5) | m6 | 30 | |

| PC080 | 19(2428) | 110 | 130 | 62 | 160 | 200(80B5) | m8 | 40 | |

| PC090 | 24(1928) | 110 | 130 | 62 | 160 | 200(90B5) | m8 | 50 |

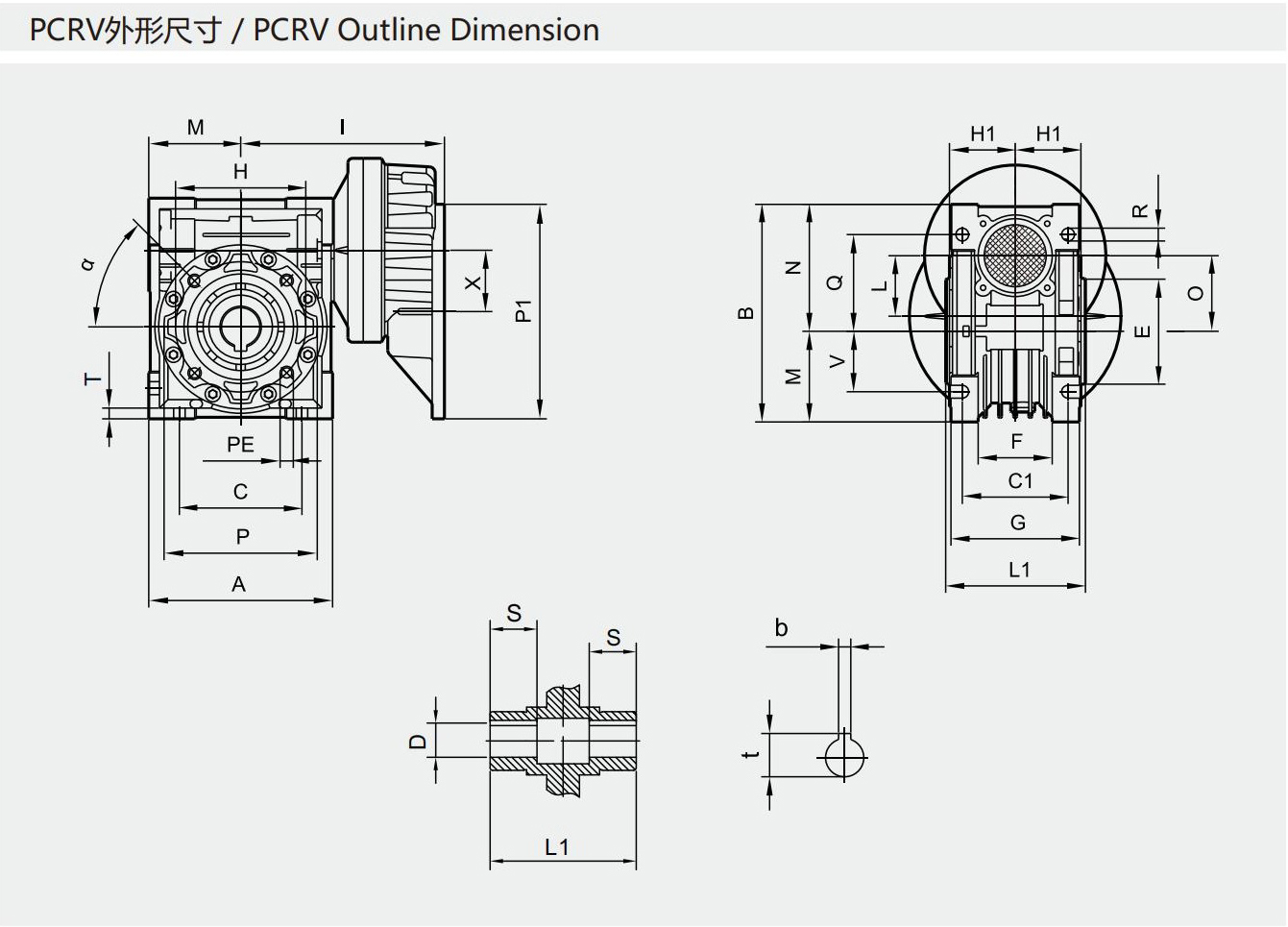

| PCRV | A | B | C | C1 | D(H7) | E(h8) | F | G | H | H1 | L1 | M | N | O | P | P1 | X | ||

| 063/040 | 100 | 121.5 | 70 | 60 |

18(19) |

60 | 43 | 71 | 75 | 36.5 | 117 | 40 | 78 | 50 | 71.5 | 40 | 87 | 140 | 43 |

| 063/050 | 120 | 144 | 80 | 70 |

25(24) |

70 | 49 | 85 | 85 | 43.5 | 127 | 40 | 92 | 60 | 84 | 50 | 100 | 140 | 43 |

| 063/063 | 144 | 174 | 100 | 85 |

25(28) |

80 | 67 | 103 | 95 | 53 | 142 | 40 | 112 | 72 | 102 | 63 | 110 | 140 | 43 |

| 071/050 | 120 | 144 | 80 | 70 |

25(24) |

70 | 49 | 85 | 85 | 43.5 | 137 | 50 | 92 | 60 | 84 | 50 | 100 | 160 | 54 |

| 071/063 | 144 | 174 | 100 | 85 | 25(28 | 80 | 67 | 103 | 95 | 53 | 152 | 50 | 112 | 72 | 102 | 63 | 110 | 160 | 54 |

| 071/075 | 172 | 205 | 120 | 90 |

28(35) |

95 | 72 | 112 | 115 | 57 | 169.5 | 50 | 120 | 86 | 119 | 75 | 140 | 160 | 54 |

| 071/090 | 206 | 238 | 140 | 00 |

35(38) |

110 | 74 | 130 | 130 | 67 | 186.6 | 50 | 140 | 103 | 135 | 90 | 160 | 160 | 54 |

| 080/075 | 172 | 205 | 120 | 90 | 28(35 | 95 | 72 | 12 | 115 | 57 | 186.5 | 63 | 120 | 86 | 119 | 75 | 140 | 200 | 66 |

| 080/090 | 206 | 238 | 140 | 100 | 35(38 | 110 | 74 | 130 | 130 | 67 | 203.5 | 63 | 140 | 103 | 135 | 90 | 160 | 200 | 66 |

| 080(090)/110 | 255 | 295 | 170 | 115 | 42 | 130 | - | 144 | 165 | 74 | 234 | 63 | 155 | 27.5 | 167.5 | 10 | 200 | 200 | 66 |

| 080(090)/130 | 293 | 335 | 200 | 120 | 45 | 180 | - | 155 | 215 | 81 | 253 | 63 | 170 | 147.5 |

87.5 |

30 | 250 | 200 | 66 |

| PCRV | Q | R | S | T | V | PE | b | t | α | Kg |

| 063/040 | 55 | 6.5 | 26 | 6.5 | 35 | M6x8(n=4) | 6 | 20.8(21.8) | 45° | 3.9 |

| 063/050 | 64 | 8.5 | 30 | 7 | 40 | M8x10(n=4) | 8 | 28.3(27.3) | 45° | 5.2 |

| 063/063 | 80 | 8.5 | 36 | 8 | 50 | M8x14(n=8) | 8 | 28.3(31.3) | 45° | 7.9 |

| 071/050 | 64 | 8.5 | 30 | 7 | 40 | M8x10(n=4) | 8 | 28.3(27.3) | 45° | 5.8 |

| 071/063 | 80 | 8.5 | 36 | 8 | 50 | M8x14(n=8) | 8 | 28.3(31.3) | 45° | 8.5 |

| 071/075 | 93 | 11 | 40 | 10 | 60 | M8x14(n=8) | 8 | 31.3(38.3) | 45° | 11.3 |

| 071/090 | 102 | 13 | 45 | 11 | 70 | M10x18(n=8) | 10 | 38.3(41.3) | 45° | 15.3 |

| 080/075 | 93 | 11 | 40 | 10 | 60 | M8x14(n=8) | 8(10) | 31.3(38.3) | 45° | 13.1 |

| 080/090 | 102 | 13 | 45 | 11 | 70 | M10x18(n=8) | 10 | 38.3(41.3) | 45° | 17.2 |

| 080(090)/110 | 125 | 14 | 50 | 14 | 85 | M10x18(n=8) | 12 | 45.3 | 45° | 44.5 |

| 080(090)/130 | 140 | 16 | 60 | 15 | 100 | M12x21(n=8) | 14 | 48.8 | 45° | 57.8 |