TYTB Permanent Magnet Synchronous Motor

Permanent Magnetic Synchronous Motor

One of the main features of our AC permanent magnet synchronous motors is their high efficiency. In fact, they are 8-20% more efficient than ordinary three-phase asynchronous motors in the 25%-100% load range. This high efficiency can significantly save energy by 10-40% and increase the power factor by 0.08-0.18. For example, compared with an ordinary Y2 motor, the annual power consumption of a 2.2 kW level 4 permanent magnet motor can save approximately 800 kWh per year.

In addition to high efficiency, our synchronous motors also offer outstanding reliability. The use of permanent magnet rare earth materials effectively avoids uneven magnetic fields and shaft currents caused by broken rotor guide bars, making the motor more reliable.

In addition, our synchronous motors have the ability to withstand overloads and are able to handle loads exceeding 2.5 times their rated capacity. Due to the performance characteristics of permanent magnets, the frequency of the motor is synchronized with the external power supply, the current waveform is good, the pulsating torque is reduced, and the electromagnetic noise is low when used with a frequency converter – up to 10-40dB lower than asynchronous motors of the same specifications.

Moreover, the installation dimensions of our synchronous motors are exactly the same as those of three-phase asynchronous motors. This means that they can directly replace the original asynchronous motor, and can also meet high-precision synchronous speed regulation occasions and various high-demand frequent starting requirements.

Our AC permanent magnet synchronous motors are versatile and performant, making them ideally suited for a wide range of applications across a variety of industries. Whether it’s industrial equipment, commercial machinery or other applications that require precision, efficiency and reliability, our synchronous motors deliver superior performance and energy-saving advantages.

In summary, our AC permanent magnet synchronous motors offer exceptional efficiency, reliability and performance, making them ideal for a variety of applications. Our motors are available in a variety of motor base sizes and power options and can be customized to meet specific customer requirements. Experience the advantages of high efficiency, energy saving and reliable operation of our innovative AC permanent magnet synchronous motors.

| TYTB Permanent Magnetic Synchronous Motor | poles | ||

| Type | Power | ||

| kW | HP | ||

| TYTB-8012 | 0.75 | 1 | 2P |

| TYTB-8022 | 1.1 | 1.5 | |

| TYTB-90S2 | 1.5 | 2 | |

| TYTB-90L2 | 2.2 | 3 | |

| TYTB-100L2 | 3 | 4 | |

| TYTB-112M2 | 4 | 5.5 | |

| TYTB-132S1-2 | 5.5 | 7.5 | |

| TYTB-132S2-2 | 7.5 | 10 | |

| TYTB-160M1-2 | 11 | 15 | |

| TYTB-160M2-2 | 15 | 20 | |

| TYTB-160L-2 | 18.5 | 25 | |

| TYTB-180M-2 | 22 | 30 | |

| TYTB-8014 | 0.55 | 0.75 | 4P |

| TYTB-8024 | 0.75 | 1 | |

| TYTB-90S4 | 1.1 | 1.5 | |

| TYTB-90L4 | 1.5 | 2 | |

| TYTB-100L1-4 | 2.2 | 3 | |

| TYTB-100L2-4 | 3 | 4 | |

| TYTB-112M-4 | 4 | 5.5 | |

| TYTB-132S-4 | 5.5 | 7.5 | |

| TYTB-132M-4 | 7.5 | 10 | |

| TYTB-160M-4 | 11 | 15 | |

| TYTB-160L-4 | 15 | 20 | |

| TYTB-180M-4 | 18.5 | 25 | |

| TYTB-180L-4 | 22 | 30 | |

| TYTB-90S6 | 0.75 | 1 | 6P |

| TYTB-90L6 | 1.1 | 1.5 | |

| TYTB-100L-6 | 1.5 | 2 | |

| TYTB-112M-6 | 2.2 | 3 | |

| TYTB-132S-6 | 3 | 4 | |

| TYTB-132M1-6 | 4 | 5.5 | |

| TYTB-132M2-6 | 5.5 | 7.5 | |

| TYTB-160M-6 | 7.5 | 10 | |

| TYTB-160L-6 | 11 | 15 | |

| TYTB-180L-6 | 15 | 20 | |

The Characteristics of Premium Efficiency PMSM

1.Energy-efficient

Synchronous motor has the characteristics such as high efficiency,high power factor,high reliability.The efficiency within the range 25%-100%load is higher than ordinary three-phase asynchronous motor about 8-20%,and the energy saving can be achieved 10-40%,the power factor can be increased by 0.08-0.18.

2.High reliability

Because of permanent magnetic rare earth materials,which can effectively avoid the magnetic field imbalance and axial current of the rotor broken bar,and make the motor more reliable.

3.High torque,low vibration and noise

Permanent magnet synchronous motor with overload resistance (above 2.5 times),due to the nature of the permanent magnet performance,make the motor synchronization in the external power supply frequency,current waveform,torque ripples obviously decreased.When using together with the frequency converter,the electromagnetic noise is very low,and comparing with the specifications of the asynchronous motor to reduce 10 to 40dB.

4.High applcability

The permanent magnet synchronous motor is widely used,which can directly replace the original three-phase asynchronous motor because of the installation size is the same as thee-phase asynchronous motor.It can also meet various high-preciaion synchronous speed control situations and various high requirements of frequent starting.It’s also a good product for energy conservation and saving money.

An Example of Energy Saving Benefit of PMSM and Normal Y2 Motor

| TYPE | ELECTRIC EFFCIENCY | ELECTRICTY PER HOUR | ANNUAL ELECTRICITY CONSUMPTION(8*300) | ENERGY SAVING |

| 2.2kW 4 pole permanent magnetic moto | 90% | 2.2/0.9=2.444 kWh | 5856 kWh | It wil save744yuan a year by 1 kilowathout. |

| 2.2kW 4 pole original three-phase asynchronous motor | 80% | 2.2/0.8=2.75 kWh | 6600 kWh |

The up is a comparison of a 2.2kW 4 pole permanent magnetic motor and an normal Y2 motor for annual power savings.

TYTB Series High Efficiency PMSM Motor Technology Parameters (lE5, LEVEL 1)

| 3000r/min 380V 50Hz | ||||||||||

|

TYPE |

RATED OUTPUT |

RATED SPEED |

EFFICENCY |

POWER FACTOR |

RATED CURRENT |

RATED TORQUE |

LOCKED ROTOR TORQUE |

MAX IMUM TORQUE |

LOCKED ROTOR CURRENT |

|

|

RATED TORQUE |

RATED TORQUE |

RATED CURRENT | ||||||||

| kW | HP | rpm | %η | COSφ | A | Nm | Ts/Tn | Tmax/Tn | Is/In | |

| TYTB-801-2 |

0.75 |

1 |

3000 |

84.9 |

0.99 |

1.36 |

2.38 |

2.2 |

2.3 |

6.1 |

| TYTB-802-2 |

1.1 |

1.5 |

3000 |

86.7 |

0.99 |

1.95 |

3.5 |

2.2 |

2.3 |

7 |

| TYTB-90S-2 |

1.5 |

2 |

3000 |

87.5 |

0.99 |

2.63 |

4.77 |

2.2 |

2.3 |

7 |

| TYTB-90L-2 |

2.2 |

3 |

3000 |

89.1 |

0.99 |

3.79 |

7 |

2.2 |

2.3 |

7 |

| TYTB-100L-2 |

3 |

4 |

3000 |

89.7 |

0.99 |

5.13 |

9.55 |

2.2 |

2.3 |

7.5 |

| TYTB-112M-2 |

4 |

5.5 |

3000 |

90.3 |

0.99 |

6.8 |

12.7 |

2.2 |

2.3 |

7.5 |

| TYTB-132S1-2 |

5.5 |

7.5 |

3000 |

91.5 |

0.99 |

9.23 |

17.5 |

2.2 |

2.3 |

7.5 |

| TYTB-132S2-2 |

7.5 |

10 |

3000 |

92.1 |

0.99 |

12.5 |

23.8 |

2.2 |

2.3 |

7.5 |

| TYTB-160M1-2 |

11 |

15 |

3000 |

93 |

0.99 |

18.2 |

35 |

2.2 |

2.3 |

7.5 |

| TYTB-160M2-2 |

15 |

20 |

3000 |

93.4 |

0.99 |

24.6 |

47.8 |

2.2 |

2.3 |

7.5 |

| TYTB-160L-2 |

18.5 |

25 |

3000 |

93.8 |

0.99 |

30.3 |

58.9 |

2.2 |

2.3 |

7.5 |

| TYTB-180M-2 |

22 |

30 |

3000 |

94.4 |

0.99 |

35.8 |

70 |

2.2 |

2.3 |

7.5 |

| 1500r/min 380V 50Hz | ||||||||||

|

TYPE |

RATED OUTPUT |

RATED SPEED |

EFFICENCY |

POWER FACTOR |

RATED CURRENT |

RATED TORQUE |

LOCKED ROTOR TORQUE |

MAX IMUM TORQUE |

LOCKED ROTOR CURRENT |

|

|

RATED TORQUE |

RATED TORQUE |

RATED CURRENT | ||||||||

| kW | HP | rpm | %η | COSφ | A | Nm | Ts/Tn | Tmax/Tn | Is/In | |

| TYTB-801-4 |

0.55 |

3/4 | 1500 | 84.5% | 0.99 | 1.01 | 3.5 | 2.0 | 2.5 | 6.6 |

| TYTB-802-4 |

0.75 |

1 | 1500 | 85.6% | 0.99 | 1.35 | 4.8 | 2.0 | 2.5 | 6.8 |

| TYTB-90S-4 |

1.1 |

1.5 | 1500 | 87.4% | 0.99 | 1.95 | 7.0 | 2.0 | 2.5 | 7.6 |

| TYTB-90L-4 |

1.5 |

2 | 1500 | 88.1% | 0.99 | 2.53 | 9.55 | 2.0 | 2.5 | 7.6 |

| TYTB-100L1-4 |

2.2 |

3 | 1500 | 89.7% | 0.99 | 3.79 | 14.0 | 2.0 | 2.5 | 7.6 |

| TYTB-100L2-4 | 3.0 | 4 | 1500 | 90.3% | 0.99 | 5.13 | 19.1 | 2.5 | 2 8 | 7.6 |

| TYTB-112M-4 | 4.0 | 5.5 | 1500 | 90.9% | 0.99 | 6.80 | 25.5 | 2.5 | 2.8 | 7.6 |

| TYTB-132S-4 | 5.5 | 7.5 | 1500 | 92.1% | 0.99 | 9.23 | 35.0 | 2.5 | 2.8 | 7.6 |

| TYTB-132M-4 | 7.5 | 10 | 1500 | 92.6% | 0.99 | 12.3 | 47.75 | 2.5 | 2.8 | 7.6 |

| TYTB-160M-4 | 11 | 15 | 1500 | 93.6% | 0.99 | 18.2 | 70.0 | 2.5 | 2.8 | 7.6 |

| TYTB-160L-4 | 15 | 20 | 1500 | 94.0% | 0.99 | 24.7 | 95.5 | 2.5 | 2.8 | 7.6 |

| TYTB-180M-4 | 18.5 | 25 | 1500 | 94.3% | 0.99 | 30.3 | 117.8 | 2.5 | 2 8 | 7.6 |

| TYTB-180L-4 | 22 |

30 |

1500 | 94.7% | 0.99 | 35.9 | 140 | 2.5 | 2.8 | 7.6 |

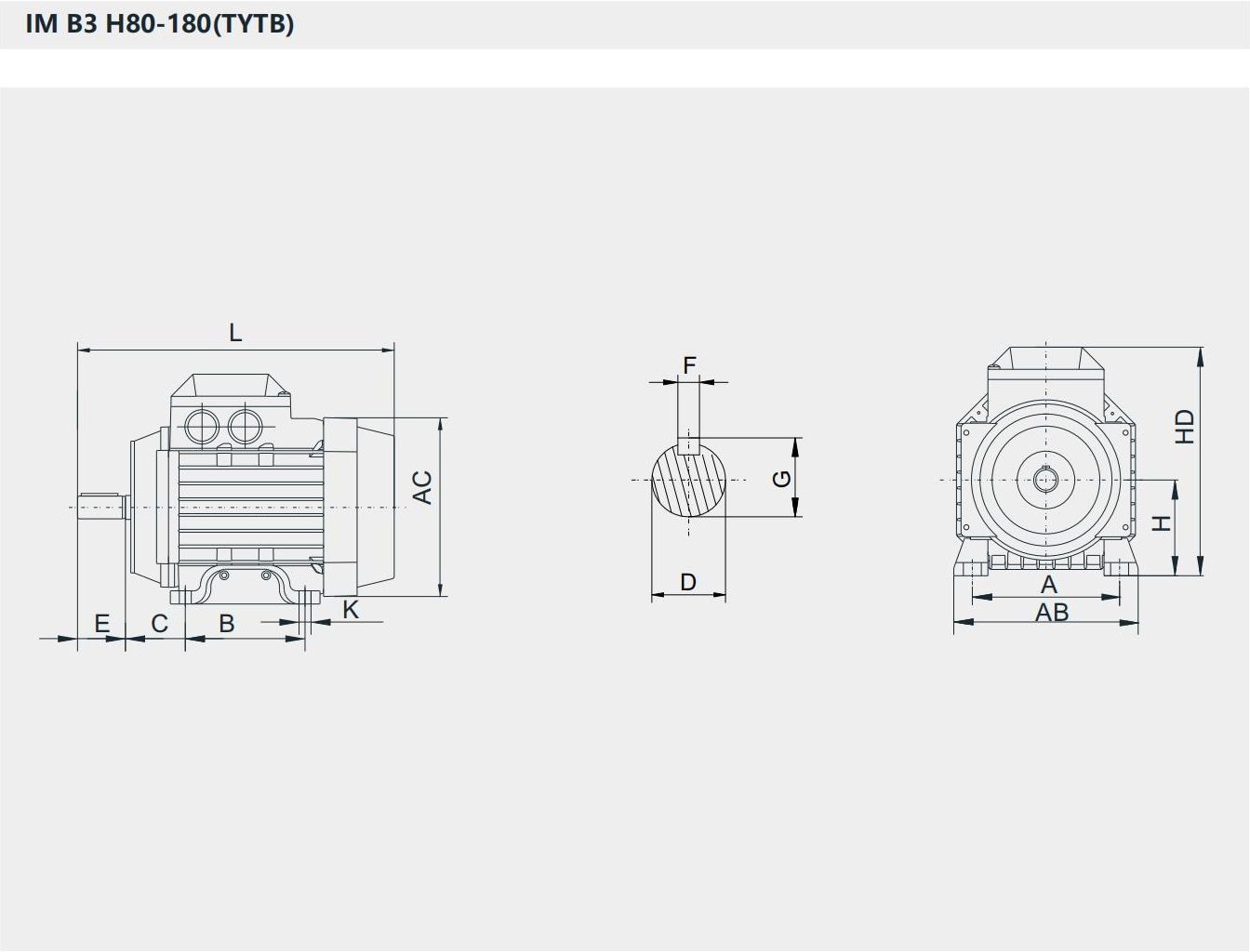

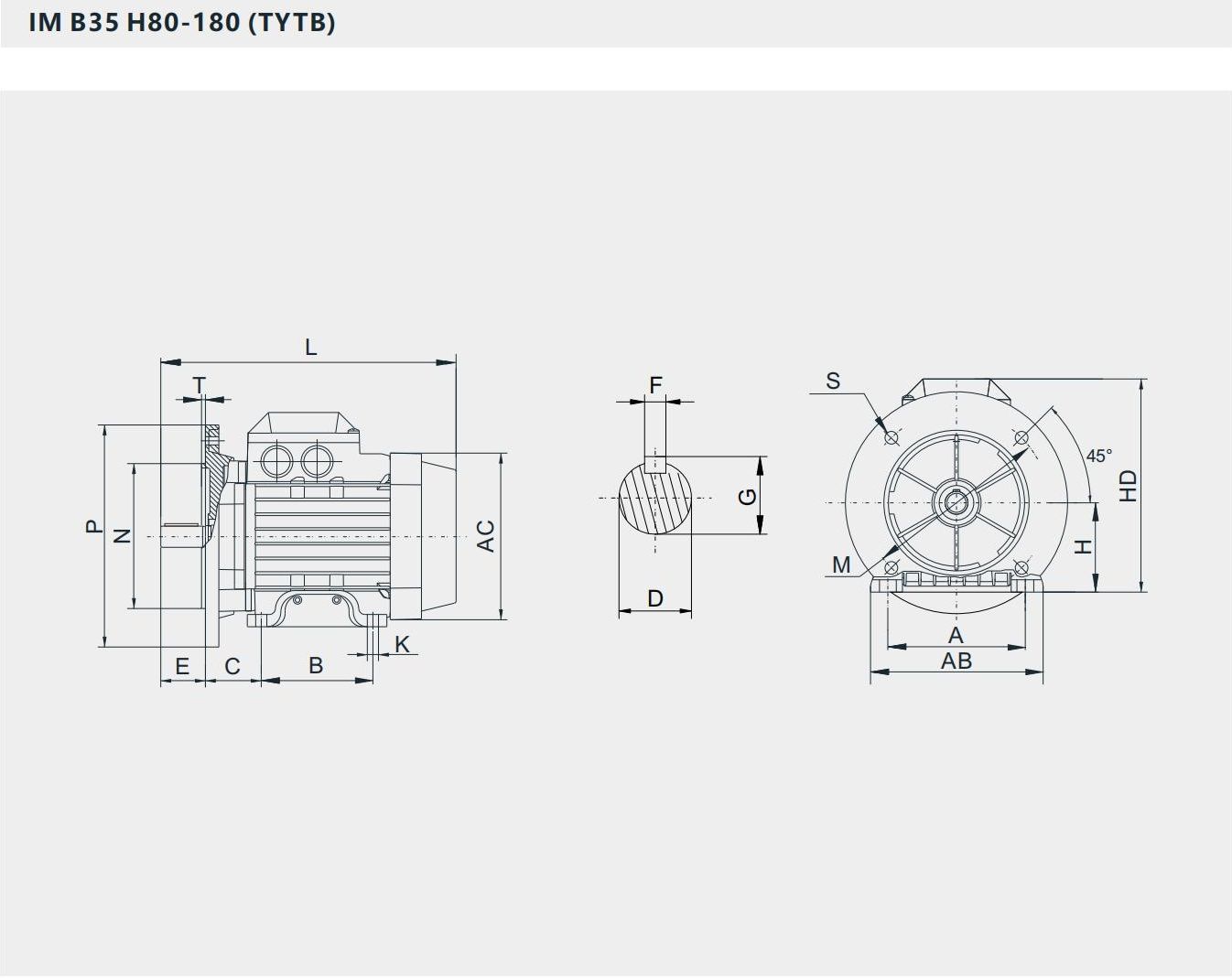

TYTB Series High Efficiency PMSM Motor Installation Dimension (lE5, LEVEL 1)

|

Frame size |

Installation Dimensions |

||||||||||||

| A | B | C | D | E | F | G | H | K | AB | AC | HD | L | |

| 80M | 125 | 100 | 50 | ø19 | 40 | 6 | 21.5 | 80 | ø10 | 154 | 145×145 | 190 | 270 |

| 90S | 140 | 100 | 56 | ø24 | 50 | 8 | 27 | 90 | ø10 | 180 | 160×160 | 205 | 316 |

| 90L | 140 | 125 | 56 | ø24 | 50 | 8 | 27 | 90 | ø10 | 180 | 160×160 | 205 | 326 |

| 100L | 160 | 140 | 63 | ø28 | 60 | 8 | 31 | 100 | ø12 | 205 | 185×185 | 240 | 360 |

| 112M | 190 | 140 | 70 | ø28 | 60 | 8 | 31 | 112 | ø12 | 235 | 200×200 | 270 | 400 |

| 132S | 216 | 140 | 89 | ø38 | 80 | 10 | 41 | 132 | ø12 | 261 | 245×245 | 310 | 470 |

| 132M | 216 | 178 | 89 | ø38 | 80 | 10 | 41 | 132 | ø12 | 261 | 245×245 | 310 | 470 |

| 160M | 254 | 210 | 108 | ø42 | 110 | 12 | 45 | 160 | ø14.5 | 320 | 320×320 | 450 | 620 |

| 160L | 254 | 254 | 108 | ø42 | 110 | 12 | 45 | 160 | ø14.5 | 320 | 320×320 | 450 | 660 |

| 180M | 279 | 241 | 121 | ø48 | 110 | 14 | 51.5 | 180 | ø14.5 | 355 | 360×360 | 500 | 700 |

| 180L | 279 | 279 | 121 | ø48 | 110 | 14 | 51.5 | 180 | ø14.5 | 355 | 360×360 | 500 | 740 |

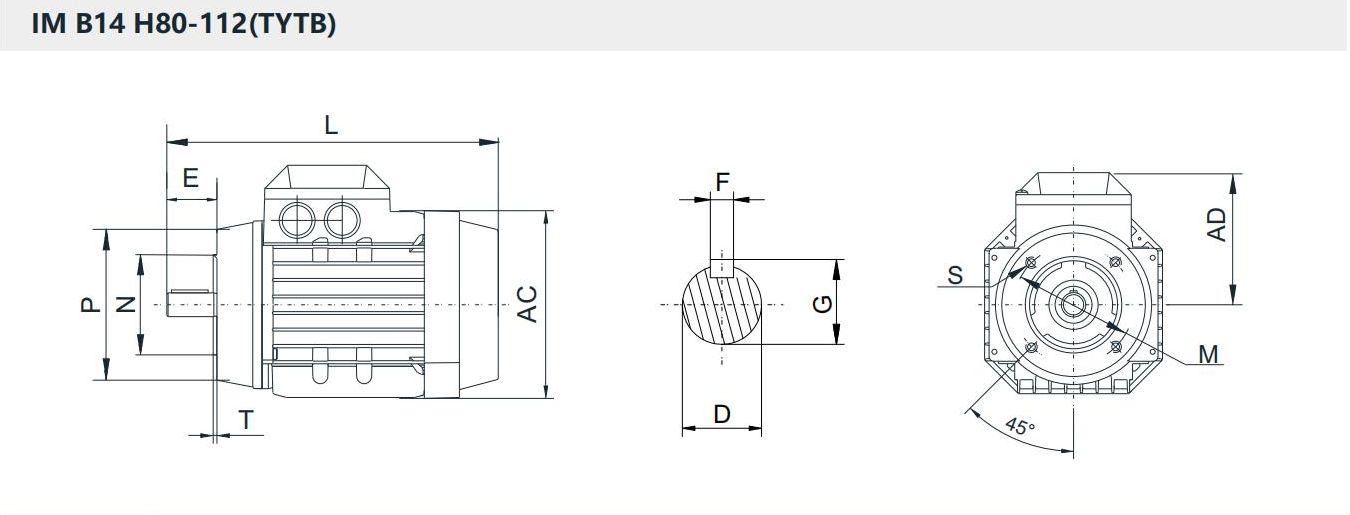

| Frame size |

Installation Dimensions |

|||||||||||

| D | E | F | G | M | N | P | S | T | AC | AD | L | |

| 80M | ø19 | 40 | 6 | 21.5 | 100 | 80 | 120 | M6 | 3.0 | 145×145 | 115 | 270 |

| 90S | ø24 | 50 | 8 | 27 | 115 | 95 | 140 | M8 | 3.0 | 160×160 | 122 | 316 |

| 90L | ø24 | 50 | 8 | 27 | 115 | 95 | 140 | M8 | 3.0 | 160×160 | 122 | 326 |

| 100L | ø28 | 60 | 8 | 31 | 130 | 110 | 160 | M8 | 3.5 | 185×185 | 137 | 370 |

| 112M | ø28 | 60 | 8 | 31 | 130 | 110 | 160 | M8 | 3.5 | 200×200 | 155 | 400 |

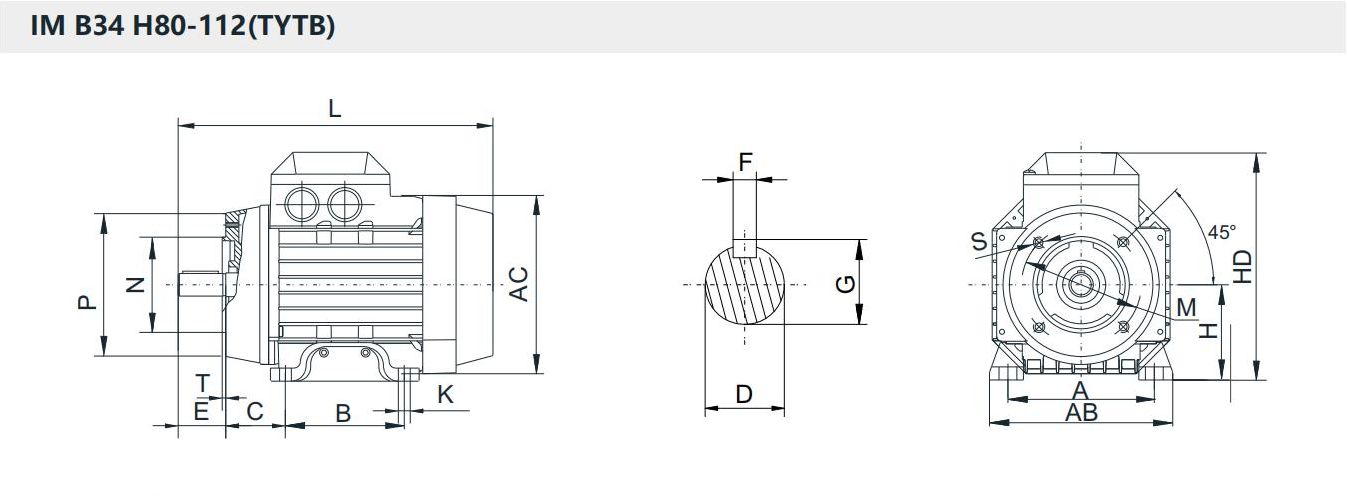

|

Frame size |

Installation Dimensions |

|||||||||||||||||

| A | B | C | D | E | F | G | H | K | M | N | P | S | T | AB | AC | HD | L | |

| 80M |

125 |

100 |

50 |

ø19 |

40 |

6 |

21.5 |

80 |

ø10 |

100 |

80 |

120 |

M6 | 3.0 |

154 |

145×145 |

190 |

270 |

| 90S |

140 |

100 |

56 |

ø24 |

50 |

8 |

27 |

90 |

ø10 |

115 |

95 |

140 |

M8 | 3.0 |

180 |

160×160 |

205 |

316 |

| 90L |

140 |

125 |

56 |

ø24 |

50 |

8 |

27 |

90 |

ø10 |

115 |

95 |

140 |

M8 | 3.0 |

180 |

160×160 |

205 |

326 |

| 100L |

160 |

140 |

63 |

ø28 |

60 |

8 |

31 |

100 |

ø12 |

130 |

110 |

160 |

M8 |

3.5 |

205 |

185×185 |

240 |

370 |

| 112M |

190 |

140 |

70 |

ø28 |

60 |

8 |

31 |

112 |

ø12 |

130 |

110 |

160 |

M8 |

3.5 |

235 |

200×200 |

270 |

400 |

|

Frame size |

Installation Dimensions |

|||||||||||

| D | E | F | G | M | N | P | S | T | AC | AD | L | |

| 80M | ø19 | 40 | 6 | 21.5 | 165 | 130 | 200 | 12 | 3.5 | 145×145 | 115 | 270 |

| 90S | ø24 | 50 | 8 | 27 | 165 | 130 | 200 | 12 | 3.5 | 160×160 | 122 | 316 |

| 90L | ø24 | 50 | 8 | 27 | 165 | 130 | 200 | 12 | 3.5 | 160×160 | 122 | 326 |

| 100L 112M | ø28 | 60 | 8 | 31 | 215 | 180 | 250 | 14.5 | 4 | 185×185 | 137 | 360 |

| ø28 | 60 | 8 | 31 | 215 | 180 | 250 | 14.5 | 4 | 200×200 | 155 | 400 | |

| 132S | ø38 | 80 | 10 | 41 | 265 | 230 | 300 | 14.5 | 4 | 245×245 | 180 | 470 |

| 132M | ø38 | 80 | 10 | 41 | 265 | 230 | 300 | 14.5 | 4 | 245×245 | 180 | 470 |

| 160M 160L | ø42 | 110 | 12 | 45 | 300 | 250 | 350 | 18.5 | 5 | 320×320 | 290 | 620 |

| ø42 | 110 | 12 | 45 | 300 | 250 | 350 | 18.5 | 5 | 320×320 | 290 | 660 | |

| 180M | ø48 | 110 | 14 | 51.5 | 300 | 250 | 350 | 18.5 | 5 | 360×360 | 320 | 700 |

| 180L | ø48 | 110 | 14 | 51.5 | 300 | 250 | 350 | 18.5 | 5 | 360×360 | 320 | 740 |

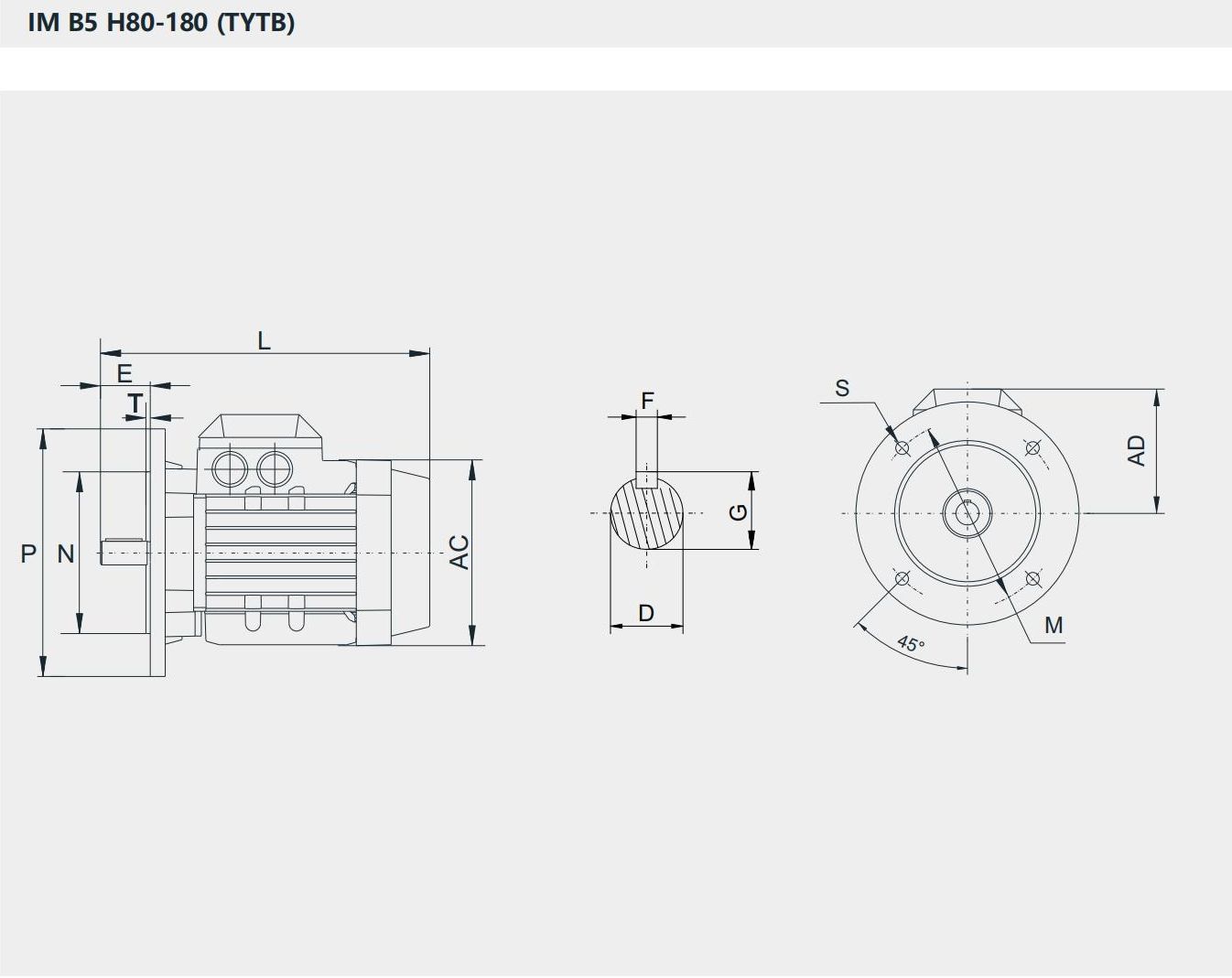

|

Frame size |

Installation Dimensions |

|||||||||||||||||

|

A |

B |

C |

D | E | F | G | H | K | M | N | P | S | T | AB | AC | HD | L | |

| 80M | 125 | 100 | 50 | ø19 | 40 | 6 | 21.5 | 80 | ø10 | 165 | 130 | 200 | 12 | 3.5 | 154 | 145×145 | 190 | 270 |

| 90S |

140 |

100 |

56 |

ø24 | 50 | 8 | 27 | 90 | ø10 | 165 | 130 | 200 | 12 | 3.5 | 180 | 160×160 | 205 | 316 |

| 90L |

140 |

125 |

56 |

ø24 | 50 | 8 | 27 | 90 | ø10 | 165 | 130 | 200 | 12 | 3.5 | 180 | 160×160 | 205 | 326 |

| 100L 112M | 160 | 140 | 63 | ø28 | 60 | 8 | 31 | 100 | ø12 | 215 | 180 | 250 | 14.5 | 4 | 205 | 185×185 | 240 | 360 |

| 190 | 140 | 70 | ø28 | 60 | 8 | 31 | 112 | ø12 | 215 | 180 | 250 | 14.5 | 4 | 235 | 200×200 | 270 | 400 | |

| 132S | 216 | 140 | 89 | ø38 | 80 | 10 | 41 | 132 | ø12 | 265 | 230 | 300 | 14.5 | 4 | 261 | 245×245 | 310 | 470 |

| 132M | 216 | 178 | 89 | ø38 | 80 | 10 | 41 | 132 | ø12 | 265 | 230 | 300 | 14.5 | 4 | 261 | 245×245 | 310 | 470 |

| 160M 160L | 254 | 210 | 108 | ø42 | 110 | 12 | 45 | 160 | ø14.5 | 300 | 250 | 350 | 18.5 | 5 | 320 | 320×320 | 450 | 620 |

| 254 | 254 | 108 | ø42 | 110 | 12 | 45 | 160 | ø14.5 | 300 | 250 | 350 | 18.5 | 5 | 320 | 320×320 | 450 | 660 | |

| 180M |

279 |

241 |

121 |

ø48 | 110 | 14 | 51.5 | 180 | ø14.5 | 300 | 250 | 350 | 18.5 | 5 | 355 | 360×360 | 500 | 700 |

| 180L |

279 |

279 |

121 |

ø48 | 110 | 14 | 51.5 | 180 | ø14.4 | 300 | 250 | 350 | 18.5 | 5 | 355 | 360×360 | 500 | 740 |